Using RFID for Asset Tracking

Every business has assets that it uses to streamline it’s operations. Whether it be laptops to simplify IT operations or machinery to conduct manufacturing, it’s important the business understands where these assets are and the operational status of the items.

RFID technology provides simplification of accountability of assets by making it easy to collect data regarding the asset. The technology is being used today to track and manage assets for use cases like fixed asset management, IT asset tracking, tool tracking among others.

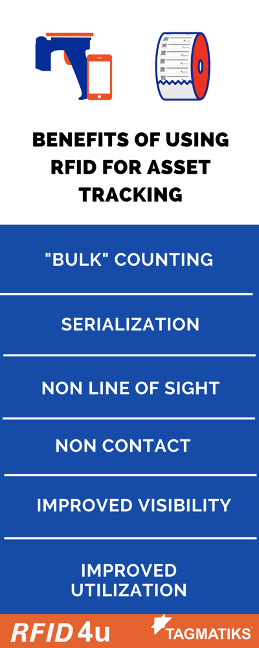

Explore below for key benefits.

Bulk Counting: RFID technology collects data in “bulk”. Specifically, UHF RFID allows users to scan multiple items which are tagged with RFID tags and labels using an RFID reader or handheld. This benefit helps cut down on traditional manual tasks.

Serialization: A hidden benefit of adopting RFID is that each RFID tag / label is designed to be unique by nature. This allows collection of data to be uniquely identified so that users can report historically on each asset.

Non line of sight: RFID tags don’t necessary have to have line of sight with the RFID reader. This simplifies the collection of data. Imagine having to scan a barcode on the computer that is hidden under a wooden desk. It would be tiresome to crawl under the desk and find the barcode. With RFID, these workflows can be automated.

Non Contact: Scan assets without having to come into contact with the item.

Improved Visibility: Take better business decisions as you get visibility to what assets are located is which areas of your business. More importantly, understand if assets are going missing before they are critically needed.

Improved Utilization: Reduce unused assets by allocating assets appropriately.

Recent Posts

-

Best RFID Tags for Metal Environments: Types & Applications

Radio Frequency Identification (RFID) technology is revolutionizing asset tracking, inventory manage …Jul 10th 2025 -

Stages of RFID Seal Tags: From Manufacturing to Application

Radio Frequency Identification (RFID) technology has revolutionized supply chain management, asset t …Jun 30th 2025 -

Ultimate Comparison Guide: Zebra RFD40 Premium Plus vs. RFD9090 vs. MC3330xR UHF RFID Readers

In the evolving world of RFID-based asset tracking, inventory management, and supply chain automatio …Jun 26th 2025