RFID Portal Deployment Checklist: From Site Survey to Calibration

Deploying an RFID portal involves far more than mounting readers and antennas. It requires a methodical approach to ensure optimal tag readability, minimal interference, and seamless integration with backend systems. This checklist outlines each critical phase of deployment, offering actionable steps and best practices to guide your team from planning to performance tuning.

1. Site Survey and Environmental Assessment

Before any hardware is installed, conduct a thorough site survey to understand the physical and RF environment.

Objectives:

- Identify read zones and traffic flow

- Assess potential sources of RF interference

- Document mounting surfaces and power/network availability

Key Actions:

- Map portal locations (e.g., dock doors, conveyor belts, entry/exit points)

- Measure ambient RF noise using spectrum analyzers

- Identify materials (metal, liquid, concrete) that may affect signal propagation

- Evaluate lighting, temperature, and humidity conditions

- Confirm availability of power outlets and Ethernet drops

Deliverables:

- Site survey report with annotated floor plans

- Environmental interference log

- Infrastructure readiness checklist

2. Hardware Selection and Configuration

Choose components based on operational requirements and environmental constraints.

Components:

- RFID Readers: Fixed UHF readers with multi-port support

- Antennas: Directional or omnidirectional, depending on coverage needs

- Cables and Mounts: Shielded coaxial cables, adjustable brackets

- Enclosures: Weatherproof or ruggedized for industrial settings

- Sensors (optional): Motion, light, or presence sensors for portal activation

Configuration Considerations:

- RFID Reader power settings (Tx power, sensitivity)

- Antenna gain and beamwidth

- Tag orientation and expected velocity

- Reader-to-host communication protocol (TCP/IP, PoE, serial)

3. Tag Selection and Placement Strategy

Tag performance is highly dependent on type, placement, and orientation.

Selection Criteria:

- Tag type: Passive UHF, on-metal, near-liquid, ruggedized

- Form factor: Label, hard tag, embedded

- Read range requirements

- Surface compatibility

Placement Guidelines:

- Avoid placing tags near metal edges or liquid containers unless using specialized tags

- Maintain consistent orientation across tagged items

- Test tag readability at various angles and speeds

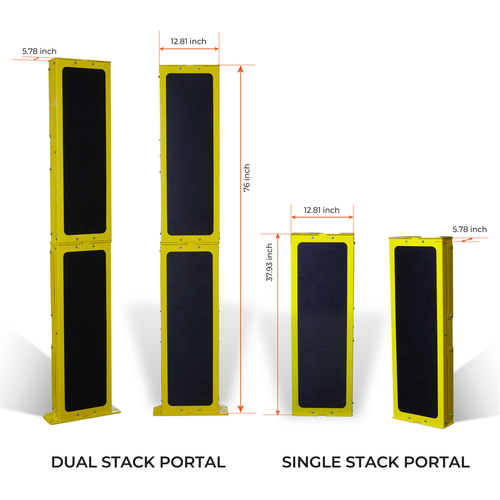

4. Portal Design and Installation

Design the portal to maximize read accuracy and minimize blind spots.

Structural Design:

- Define portal dimensions based on item size and movement

- Use side and overhead antennas for full coverage

- Incorporate shielding or RF absorbent materials to reduce reflections

Installation Steps:

- Mount antennas securely at calculated angles

- Install readers in protected enclosures

- Route and secure cables to avoid signal loss

- Connect to power and network infrastructure

- Label all components for maintenance tracking

5. Software Integration and Middleware Setup

Ensure seamless data flow from readers to enterprise systems.

Integration Tasks:

- Configure reader IPs and assign logical zones

- Set up middleware for tag filtering, event handling, and data normalization

- Connect to WMS, ERP, or asset tracking platforms via APIs or message queues

- Implement tag authentication and duplicate suppression logic

Middleware Features to Enable:

- Timestamping and location tagging

- Tag read thresholds and confidence scoring

- Exception alerts (e.g., missed reads, unauthorized tags)

6. Testing and Validation

Before going live, validate system performance under real-world conditions.

Test Scenarios:

- Single and bulk item reads

- Varying tag orientations and speeds

- Environmental stress tests (temperature, humidity)

- Interference simulation (metal carts, forklifts)

Metrics to Capture:

- Read rate (% of tags detected)

- Missed read count

- Read zone overlap and leakage

- Latency between tag read and data capture

7. Calibration and Optimization

Fine-tune system parameters to achieve consistent, high-accuracy reads.

Calibration Steps:

- Adjust the reader Tx power to balance the range and interference

- Modify antenna angles and gain settings

- Refine tag placement based on read zone heatmaps

- Enable dynamic power control if supported

Optimization Tools:

- Reader diagnostics and RSSI logs

- Tag traceability reports

- Middleware analytics dashboards

8. Documentation and Training

Ensure long-term maintainability and operational readiness.

Documentation:

- Deployment diagrams and wiring schematics

- Reader and antenna configuration files

- Tag placement guides

- Maintenance schedules

Training:

- Staff training on portal operation and troubleshooting

- IT training on middleware and data integration

- Safety protocols for RF exposure and equipment handling

9. Maintenance and Continuous Improvement

Post-deployment, establish routines for monitoring and enhancement.

Maintenance Tasks:

- Periodic hardware inspections

- Firmware updates for readers and middleware

- Recalibration after layout changes or seasonal shifts

Continuous Improvement:

- Analyze read failures and false positives

- Incorporate feedback from operations teams

- Benchmark against KPIs (inventory accuracy, throughput, asset visibility)

This checklist provides a structured roadmap for deploying RFID portals that deliver reliable, scalable performance.

Recent Posts

-

RFID Label Sizes & Formats Guide 2026

Radio Frequency Identification (RFID) labels are the backbone of modern asset tracking, inventory ma …Jan 23rd 2026 -

RFID Labels for Inventory: Formats, Adhesives & Durability GuideMeta Description

RFID labels may look simple on the surface, but they are engineered components that directly influen …Jan 17th 2026 -

RFID Gate Portals in Retail and Warehouses

The landscape of retail and warehouse operations is undergoing a profound transformation, moving awa …Dec 18th 2025