RFID Gate Portals in Retail and Warehouses

The landscape of retail and warehouse operations is undergoing a profound transformation, moving away from labor-intensive, error-prone manual tracking towards highly automated, real-time data capture. At the heart of this revolution lies the Radio Frequency Identification (RFID) Gate Portal, often simply called an RFID Gate. These intelligent checkpoints are no longer an experimental technology; they are becoming essential infrastructure for businesses aiming for near-perfect inventory accuracy, superior loss prevention, and optimized supply chain efficiency.

1. Understanding the Core Technology

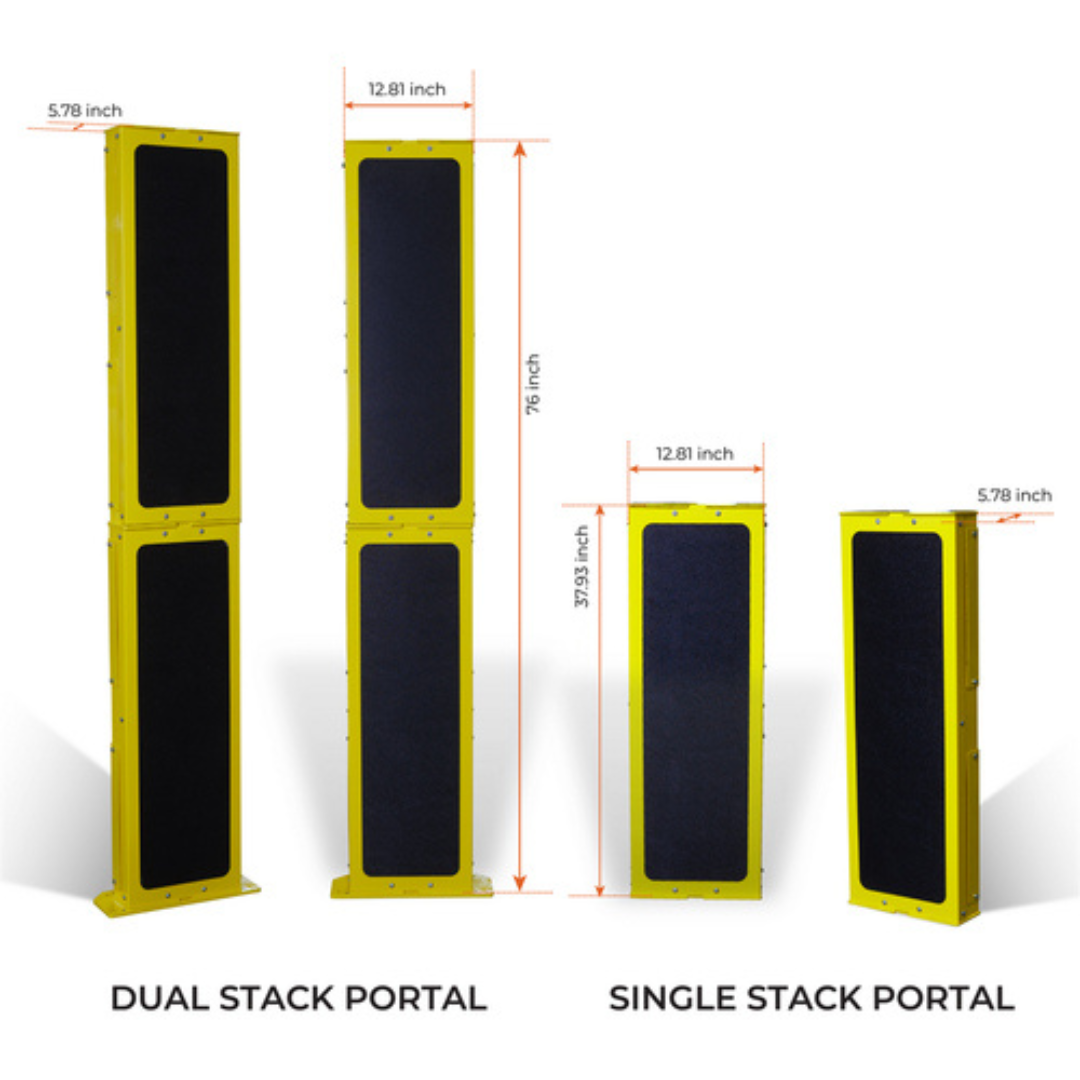

An RFID gate portal is a fixed installation designed to automatically detect and register all RFID-tagged items or assets passing through a specific choke point, such as a doorway, dock door, or conveyor belt.

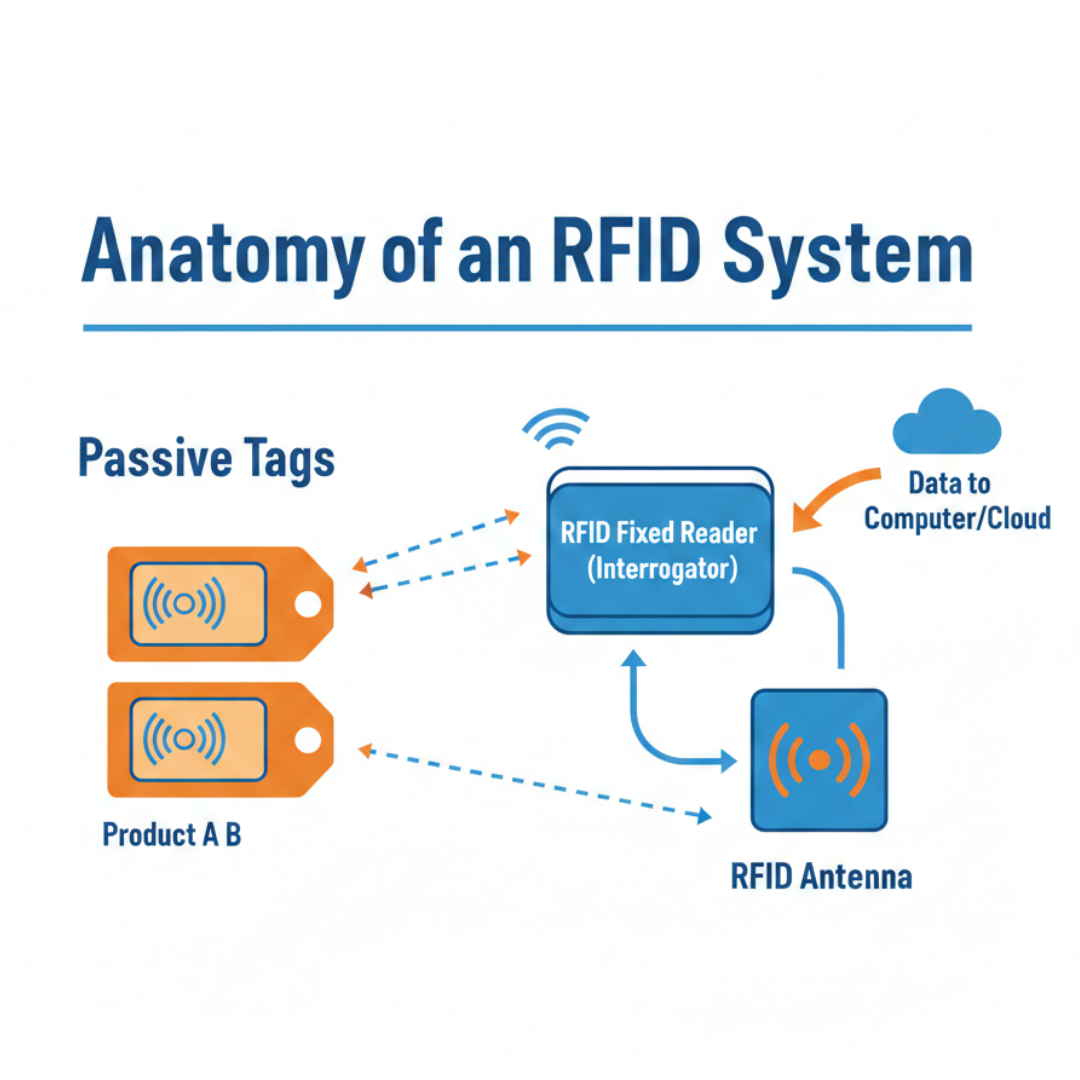

1.1 The Anatomy of an RFID System

To understand the gate portal, one must first grasp the three fundamental components of any RFID system:

Passive Tags: Most common for inventory tracking. They have no internal power source and rely on the radio waves emitted by the reader to energize their chip and send a response. They are inexpensive and ideal for high-volume, low-value goods (e.g., apparel).

RFID Reader: The "brain" of the system, often integrated into the gate structure. It emits a radio frequency (RF) signal to activate the tags and receives the tag's data response. Readers are typically categorized as fixed (used in portals).

RFID Antenna: This component transmits the reader’s signal into a "read zone" (the portal area) and captures the return signal from the tags. The design, size, and polarization of the antenna are crucial for maximizing the read range and accuracy within the portal environment.

The Portal Mechanism

The gate portal is essentially a specialized housing for one or more fixed RFID readers and multiple antennas, strategically positioned to create a uniform and reliable read zone.

- Operation: As an item with a passive UHF (Ultra-High Frequency) RFID tag passes through the portal, the reader's antenna continuously broadcasts a radio signal. The tag's antenna captures this energy, powering the microchip.

- Data Processing: The reader decodes the data, applies a time-stamp and location (the portal ID), and transmits this filtered information to a central RFID middleware layer, which then integrates it with the business's existing Warehouse Management System (WMS), Enterprise Resource Planning (ERP), or Inventory Management System (IMS).

Strategic Deployment in Retail Environments

In retail, the RFID gate portal serves dual, mission-critical functions: inventory control and loss prevention.

Loss Prevention: RFID gates at the store entrance/exit are a superior evolution of traditional systems.

Proactive Deterrence: When an unpaid item with an RFID tag passes through the exit gate, the system detects the unique tag ID and triggers an audible and/or visual alarm, alerting staff.

Item-Level Detail: Systems that only trigger notifications, the RFID system knows exactly which specific product (SKU, size, color, serial number) has been taken, providing valuable data for loss analysis and preventing the immediate need to check every item in a bag.

Internal/Vendor Control: By tagging items at the source (source-tagging) and monitoring movement through backroom doors, retailers can track items from "source to sale," making it easier to pinpoint where internal shrinkage or vendor fraud occurs.

Inventory Accuracy and Visibility

Retail portals provide real-time updates on merchandise movement between critical zones.

Backroom to Sales Floor: Portals installed between the backroom and the sales floor track when new inventory is moved out for display. This instantly updates the system, ensuring staff and customers know exactly what is available on the floor, dramatically reducing "out-of-shelf but in-store" scenarios.

Receiving/Shipping: Portals at the back dock automatically verify incoming shipments against the Purchase Order (PO) and outgoing returns, accelerating the receiving process and reducing manual errors by validating carton or pallet contents in bulk.

Enabling New Experiences: RFID portals facilitate streamlined, future-forward processes like checkout of Items.

Operational Excellence in Warehouses and Distribution Centers (DCs)

In a warehouse, RFID gate portals are fundamental to automating supply chain checkpoints, leading to massive gains in throughput and data precision.

Dock Door Portals (Receiving and Shipping)

These are the most common and high-value applications in a DC.

- Automated Verification: As pallets, cases, or roll cages pass through the dock door portal on inbound trucks (receiving) or outbound trucks (shipping), the gate automatically reads all item, case, or pallet tags simultaneously.

- PO Matching: The system instantly validates the physical contents against the Advanced Shipping Notice or customer order/manifest. Any discrepancies (e.g., missing items, wrong product, incorrect quantity) are immediately flagged for correction before the truck leaves the dock or the goods are put away. This is critical for preventing costly chargebacks and mis-shipments.

- Real-Time WMS Updates: Inventory records are updated in real-time. For receiving, the system knows the items have physically arrived and are ready for put-away. For shipping, the item's location is updated from "in stock" to "shipped," providing a live, accurate view of stock levels.

- Work-In-Process (WIP) Tracking: In manufacturing or fulfillment, portals along a conveyor belt track items as they move through different production or packaging stages, providing a detailed audit trail and optimizing flow.

- Cycle Counting & Audits: Automated reads at transition points contribute to continuous, real-time cycle counting, drastically reducing the need for disruptive, manual full-inventory counts.

- Benefits: The ROI of Automation

The capital investment required for RFID implementation is justified by the measurable return on investment (ROI) derived from the following key benefits:

|

Benefit Category |

Impact in Retail/Warehouse |

Typical Improvement |

|

Inventory Accuracy |

Eliminates human error from manual scanning and counting. Provides a definitive, real-time count. |

Boosts accuracy from a typical 65-75% (barcode) to 93-99% |

|

Loss Prevention (Shrinkage) |

Identifies the exact item stolen, deters shoplifters, and flags internal theft/fraud points. |

Significant reduction in inventory shrinkage and loss |

|

Operational Speed |

Scans hundreds of items instantaneously, eliminating the line-of-sight requirement. |

25x faster cycle counts; 90% faster shipping/receiving processes |

|

Labor Efficiency |

Automates data capture, freeing employees from counting/scanning to focus on value-added tasks.. |

Reduced labor costs and improved staff productivity |

|

Sales and Availability |

Accurate inventory leads to fewer stockouts and better product availability on the sales floor. |

Reported 1.5% to 5.5% increase in sales |

- Challenges and Considerations for Implementation

Despite the overwhelming benefits, deploying RFID gate portals is not without its challenges.

High Initial Cost: The upfront investment in fixed readers, antennas, complex software/middleware, and the cost of billions of tags can be substantial compared to a simple barcode system. However, tag prices are decreasing rapidly.

Environmental Interference: The performance of RFID can be impacted by certain environmental factors:

Metal: Metal surfaces (racking, containers) can reflect radio waves, creating dead spots or multi-path interference.

Liquids: Water or liquid-heavy products (beverages, frozen foods) can absorb RF energy, reducing the tag's read range.

Mitigation: This requires expert system design, careful antenna placement, specific tag types for metal/liquid environments, and rigorous site surveys.

Conclusion: The Future is Gate-Controlled

The RFID gate portal stands as a critical enabler of the modern, hyper-efficient supply chain. By providing automatic, accurate, and real-time visibility of inventory and assets as they transition between key operational zones—from the factory floor to the store exit—it eliminates friction, cuts shrinkage, and directly enhances the customer experience.

For retailers, the gate is an indispensable tool for maximizing sales availability. For warehouses, it is the ultimate validator, ensuring that what the system says is moving is precisely what is in motion. As tag costs continue to drop and integration complexity is streamlined by off-the-shelf middleware, the RFID gate portal will become the standard fixture for any business prioritizing operational excellence and complete item-level control.

Recent Posts

-

How RFID Handheld Readers Can Be Used with GPS for Asset Location Tracking

Asset tracking has become a critical challenge across industries such as logistics, warehousing, hea …Feb 26th 2026 -

How to Choose the Best RFID Printer: A Complete Buyer's Guide

1. What is an RFID Printer (and Why Do You Need One)? An RFID (Radio Frequency Identification) print …Feb 17th 2026 -

Zebra RFD40-M Premium Plus UHF RFID Sled

The Zebra RFD40M Premium Plus UHF RFID Sled is a modular, high-performance RFID reader that attaches …Feb 9th 2026