What to Consider as a Retailer When Choosing RFID Label

Radio Frequency Identification (RFID) has become a cornerstone of modern retail operations. From inventory visibility and loss prevention to automated checkout and supply chain traceability, RFID enables retailers to enhance efficiency, accuracy, and customer experience. However, successful RFID implementation hinges critically on one key component—the RFID label.

Often overlooked in favor of readers and software, RFID labels (also known as RFID tags or inlays) are the fundamental carriers of item-level data. Choosing the wrong label can result in poor read performance, inventory mismatches, and operational disruptions. Therefore, it is vital for retailers to evaluate RFID labels with precision and care.

This comprehensive guide walks you through every consideration a retailer must evaluate when selecting the right RFID label for their operations.

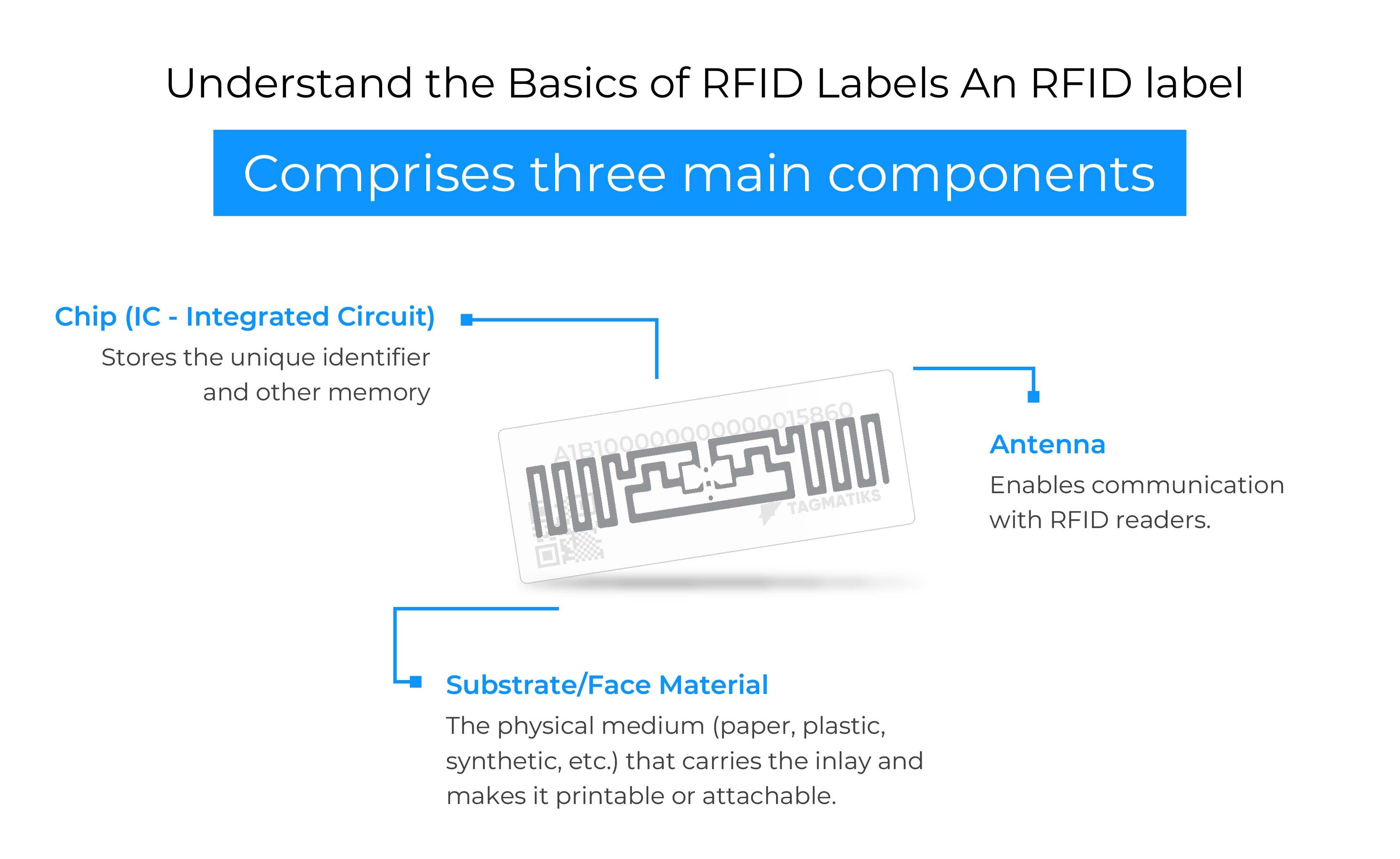

1. Understand the Basics of RFID Labels

An RFID label comprises three main components:

- Chip (IC - Integrated Circuit): Stores the unique identifier and other memory.

- Antenna: Enables communication with RFID readers.

- Substrate/Face Material: The physical medium (paper, plastic, synthetic, etc.) that carries the inlay and makes it printable or attachable.

RFID labels can be passive (no battery) or active (with battery). Retailers almost exclusively use passive UHF RFID labels due to their cost-effectiveness and suitability for item-level tagging.

2. Determine the Label’s Application Use Case

Start by understanding where and how the label will be used. Key use case questions include:

- Will the label be applied at the item, case, or pallet level?

- Is it for apparel, electronics, perishables, pharmaceuticals, or general merchandise?

- Will the label remain on the product for its entire lifecycle, or will it be removed at checkout?

The use case helps narrow down the type, size, adhesive, and material of the label needed.

3. Choose the Right Label Size and Form Factor

RFID label size affects both antenna performance and print space. The antenna must be properly tuned to function at optimal read ranges, and the size must match the item it's being applied to.

Factors to consider:

- Item size and shape: Large labels on small items can hinder aesthetics and usability.

- Packaging material: Metal, liquid, or foil can detune the antenna.

- Read range requirements: Larger antennas typically offer better range, but may not suit all products.

- Label location: Will it be inside the packaging, outside, or sewn into a garment?

Common label types in retail:

- Hang tags

- Sewn-in fabric labels

- Pressure-sensitive adhesive labels

- Embedded inlays in cardboard packaging

4. Evaluate Material and Adhesive Requirements

RFID labels must withstand the conditions of the retail environment.

Substrate Options:

- Paper: Cost-effective but less durable.

- Synthetic/Polyester: Water- and tear-resistant, suitable for harsh environments.

- Fabric (for apparel): Washable, flexible, and sewn-in.

Adhesive Options:

- Permanent: Long-lasting bond for packaging and shipping.

- Removable: For reusable or customer-facing items.

- Freezer/High-temp adhesive: For refrigerated or heated environments.

The choice of face material and adhesive depends on:

- Product packaging material

- Environmental conditions (humidity, temperature, moisture)

- Recyclability or removability

5. Assess Label Durability Based on Product Lifecycle

The label must remain functional for as long as it is needed. Ask the following:

- Will the item be exposed to abrasion, bending, or washing?

- Will it go through logistics, warehouses, and retail shelves?

- Does it need to be scannable after months of storage?

Garment tags may need to withstand ironing or laundering. Electronics may require tamper-evident labels. Products in cold storage or outdoors need weather-resistant labels

6. Test Read Range and Orientation Sensitivity

Not all RFID tags perform equally. You must test:

- Read range: How far can the tag be read from the reader?

- Orientation sensitivity: Can it be read when tilted or turned?

- Speed of movement: Does it work on conveyor belts or fast-moving items?

Retailers should pilot-test labels in real store and warehouse environments before mass deployment. Readability varies with factors like:

- Interference from packaging (e.g., foil, metal)

- Proximity to liquids

- Reader power and configuration

- Label positioning

7. Check Compatibility with Printers and Encoding Systems

RFID labels must be encoded (written with data) and printed for use.

Make sure your RFID labels are:

- Compatible with your printer model

- Readable and writable at your desired frequency (UHF: 860–960 MHz)

- Compliant with EPC Gen2 standards

Also check:

- Label roll/core size and dimensions

- Printing surface quality

- Durability of printed text/barcodes

- Comply with Industry Standards and Certifications

Choose RFID labels that comply with:

- EPCglobal Gen 2 (ISO 18000-6C): Global UHF RFID standard.

- Retail-specific guidelines: Walmart, Macy’s, Target, and others have specific inlay and format requirements.

- GS1 standards: For encoding serialized GTINs and other data.

Walmart's RFID Mandate: Requires suppliers to use specific RFID tags with approved inlays for certain product categories.

ARC Certification (Auburn University): Use ARC-certified inlays and labels for compliance with leading retailers.

9. Consider Label Cost and Scalability

Cost is a critical factor in large-scale retail RFID deployment. Labels are typically priced in bulk and vary based on:

- Chip type

- Antenna design

- Material quality

- Custom printing

- Volume of purchase

Low-cost labels may compromise performance or compliance. Don’t aim for the cheapest option—aim for the best cost-performance ratio.

Negotiate with suppliers for:

- Bulk pricing

- Custom printing

- Private branding

- Integration with software

10. Customization and Branding

RFID labels can be customized with:

- Store logos

- Product barcodes

- Human-readable SKU or price

- QR codes

- Marketing messages

Choose a supplier that can offer flexographic or digital printing, pre-encoding, and custom shapes or materials.

11. Ensure Sustainability and Recycling Goals

Retailers increasingly aim for eco-friendly operations. Consider labels that are:

- Plastic-free

- Recyclable

- Compostable

- Detachable for easier recycling of packaging

Look for green certifications and environmentally responsible suppliers.

12. Choose a Reliable Supplier and Supply Chain Partner

A good RFID label partner will:

- Provide samples and pilot support

- Ensure on-time delivery for global locations

- Assist with compliance and testing

- Offer technical support

- Help with label design optimization

Evaluate suppliers on:

- Portfolio variety

- Lead times

- Customization capabilities

- Quality assurance

Summary: Key Considerations When Choosing RFID Labels for Retail

|

Factor |

Description |

|

Application Use Case |

Define item-level, case-level, or pallet-level usage. |

|

Label Size & Shape |

Fit item dimensions, antenna performance, and aesthetic needs. |

|

Material & Adhesive |

Ensure the label survives product handling and environmental exposure. |

|

Durability |

Match product lifecycle—consider washability, heat, cold, or wear. |

|

Read Range & Orientation |

Test performance in real conditions, especially near metals/liquids. |

|

Printer Compatibility |

Match label size, encoding, and substrate to your RFID printer. |

|

Compliance & Certification |

EPC Gen2, ARC, Walmart mandates, GS1 data encoding. |

|

Cost & Volume |

Balance performance with bulk pricing for scalability. |

|

Customization & Branding |

Pre-print logos, barcodes, human-readable text, and more. |

|

Sustainability |

Opt for recyclable, plastic-free, or biodegradable options. |

|

Supplier Reliability |

Ensure delivery, quality, and support from established providers. |

|

Future-Readiness |

Enable new retail innovations and ensure backward compatibility. |

Final Thoughts

Choosing the right RFID label is not just a technical decision—it’s a strategic one. The label is the critical bridge between physical products and the digital world. A poor label choice can hinder read accuracy, violate retailer mandates, and create inventory chaos.

Retailers must carefully evaluate all aspects—from use case and material durability to encoding compliance and supplier credibility—before committing. By investing in the right RFID label, you ensure seamless operations, reliable data capture, and a scalable foundation for the future of smart retail.

Recent Posts

-

How RFID Handheld Readers Can Be Used with GPS for Asset Location Tracking

Asset tracking has become a critical challenge across industries such as logistics, warehousing, hea …Feb 26th 2026 -

How to Choose the Best RFID Printer: A Complete Buyer's Guide

1. What is an RFID Printer (and Why Do You Need One)? An RFID (Radio Frequency Identification) print …Feb 17th 2026 -

Zebra RFD40-M Premium Plus UHF RFID Sled

The Zebra RFD40M Premium Plus UHF RFID Sled is a modular, high-performance RFID reader that attaches …Feb 9th 2026