How to Encode Your RFID Labels as a Retailer Adopting RFID Technology

Adopting RFID (Radio Frequency Identification) technology in retail is a transformative move that enhances inventory accuracy, reduces labor costs, improves loss prevention, and enables real-time item visibility. However, one of the most critical yet often overlooked components of an effective RFID deployment is RFID label encoding.

Encoding RFID labels involves writing data onto RFID tags, typically in the form of Electronic Product Codes (EPCs) or serialized identifiers, which uniquely identify items within your inventory. Without proper encoding practices, the entire RFID system—no matter how advanced—can suffer from inconsistencies, duplication, or unreadable tags.

Table of Contents

- What is RFID Label Encoding?

- Why Encoding is Critical in Retail RFID Systems

- Types of Data Stored in RFID Tags

- Common Encoding Standards (EPC, SGTIN, etc.)

- Components of an RFID Encoding System

- Encoding Strategies for Retailers

- Step-by-Step RFID Label Encoding Process

- Encoding Hardware and Software

- Best Practices for Encoding RFID Labels

- Quality Control and Validation of Encoded Tags

- Compliance and EPCglobal Requirements

- Troubleshooting Encoding Issues

- Future-Proofing Your Encoding System

- Conclusion

1. What is RFID Label Encoding?

RFID label encoding is the process of writing unique identifiers or product-related information onto an RFID tag’s memory using an RFID printer-encoder or reader-writer device. This step typically happens before the RFID label is affixed to a product or product packaging.

Each RFID tag has:

- EPC memory (used for encoding product identity),

- User memory (optional, for additional data),

- TID memory (Tag Identifier – factory set, read-only).

2. Why Encoding is Critical in Retail RFID Systems

Proper encoding is fundamental because:

- Uniqueness: Prevents duplication of tag data.

- Traceability: Enables item-level tracking.

- System Integration: Synchronizes physical items with backend databases.

- Inventory Accuracy: Wrongly encoded tags cause miscounts and losses.

- GS1/EPC Compliance Interoperability: Ensures interoperability across supply chains.

3. Types of Data Stored in RFID Tags

Depending on the tag memory structure and your use case, you can store:

- EPC (Electronic Product Code)— A globally unique identifier for items.

- Serialized Global Trade Item Number (SGTIN) – Combination of product GTIN and serial number.

- SSCC (Serial Shipping Container Code)—For logistic units like cartons and pallets.

- Lot or Batch Numbers

- Manufacture or Expiry Dates

- Internal Inventory IDs

Note: Only necessary data should be encoded to maintain memory efficiency and improve read reliability.

4. Common Encoding Standards (EPC, SGTIN, etc.)

Retailers usually adopt GS1 standards to encode EPCs:

SGTIN-96 Format

- Company Prefix: GS1-assigned.

- Item Reference: Specific product.

- Serial Number: Unique to each item.

SSCC-96 Format

Used for encoding logistics data, such as pallet or case IDs.

GRAI-96 / GIAI-96

Used for returnable assets or internal asset management.

Why SGTIN-96 is preferred in retail: It enables item-level serialization, crucial for apparel, electronics, cosmetics, etc.

5. Components of an RFID Encoding System

To encode RFID labels, you'll need:

- RFID Labels/Tags: With sufficient memory and a proper form factor.

- RFID Printer-Encoders: Devices like Zebra ZT411,

- Encoding Software: Middleware or custom apps to manage EPC data generation and encoding.

- EPC Manager/Database: To prevent duplicates and maintain serial number integrity.

- Verification Equipment: RFID readers and tag verifiers.

6. Encoding Strategies for Retailers

Depending on your supply chain complexity, you can choose between:

In-House Encoding

- Tags are printed and encoded at your distribution centers or stores.

- Offers flexibility and real-time data synchronization.

Items Pretagged with RFID Tags Pre-Encoded Tags from Suppliers

- Vendors apply and encode tags before shipping items to you.

- Useful for large retailers with multiple suppliers.

- Requires compliance programs and verification.

7. Step-by-Step RFID Label Encoding Process

Let’s break down the complete process:

Step 1: Define the EPC Scheme

- Choose a GS1 EPC scheme (usually SGTIN-96) or define your own EPC standard/scheme

- In case of GS1 EPC scheme take for a company prefix from GS1 if not already done.

Step 2: Generate Unique EPC Numbers

- Use a centralized EPC manager or serial number generator by using Tagmatiks Print Manager.

- Avoid duplication at all costs.

Step 3: Create EPC Numbers

- Depending on finalized EPC scheme generate EPC number in HEX format

- Use a centralized EPC manager like Tagmatiks Print Manager to Avoid duplication at all costs.

- Below is an example of SGTIN - 96 EPC Scheme structure

SGTIN-96 has a 96-bit structure:

- Header (8 bits)

- Filter (3 bits)

- Partition (3 bits)

- Company Prefix (20–40 bits)

- Item Reference (24–4 bits)

- Serial Number (38 bits)

Step 4: Print and Encode Using RFID Printer

- How to Encode Your RFID Labels as a Retailer Adopting RFID Technology: RFID-enabled printers like the Zebra ZT Series.

- Integrate encoding logic into your printing software (e.g., TagMatiks Print Manager).

- Verify encoded data.

Step 5: Apply the Labels - this is not a part of encoding process

- Apply to product packaging or hang tags.

- Ensure consistent placement for optimal read performance.

Step 6: Verify Encoding

- Use handheld or fixed RFID readers to confirm readability and correctness.

- Cross-reference with your database.

8. Encoding Hardware and Software

Recommended RFID Printers

Software Options

- Zebra Designer

Middleware Integration

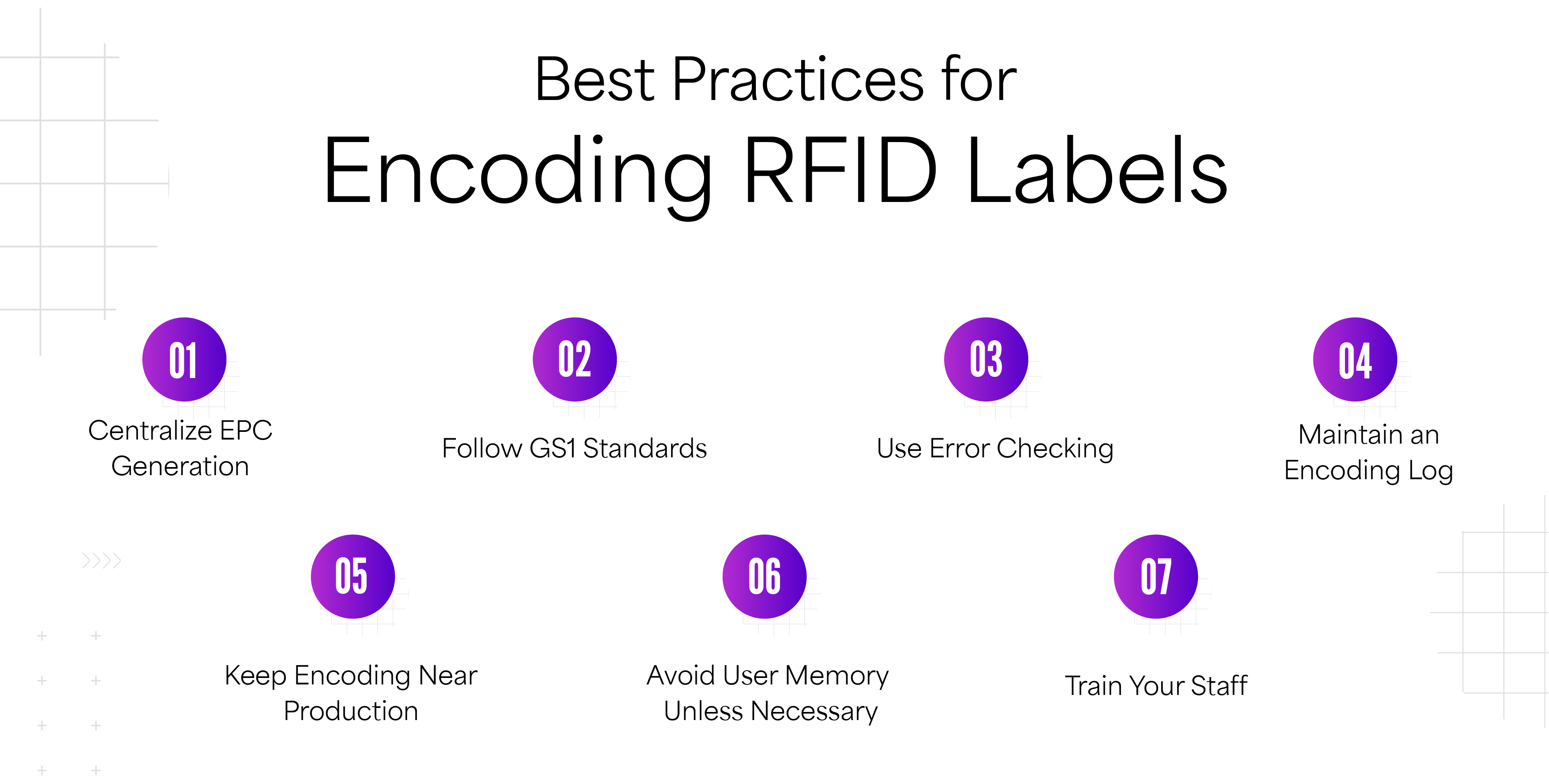

- Best Practices for Encoding RFID Labels

- Centralized EPC Generation: Avoid fragmented or manual EPC assignment.

- Follow GS1 Standards: Ensures industry interoperability.

- Use Error Checking: Validate EPC format and tag memory.

- Maintain an Encoding Log: For audit, troubleshooting, and analytics.

- Keep Encoding Near Production: Reduces logistics errors.

- Avoid User Memory Unless Necessary: EPC memory is more efficient and easier to read.

- Train Your Staff: On how to handle encoding, verification, and label placement.

10. Quality Control and Validation of Encoded Tags

After encoding, quality checks ensure the tag functions correctly:

- Readability Test: Test with handheld/fixed reader from operational distance.

- Memory Check: Confirm EPC contents match the intended format.

- Print Verification: Ensure barcodes or text on the label match the EPC data.

- Duplicate Detection: No two items should share the same EPC.

- Failure Rate Tracking: Monitor bad tag ratio; <1% is standard.

11. Compliance and EPCglobal Requirements

GS1/EPCglobal Guidelines

- GS1 prefixes and item references must be valid.

- SGTIN-96 format is required for retail-level serialization.

- Serialized identifiers must not repeat.

Retailer Mandates

Retailers like Walmart require suppliers to:

- Encode SGTIN-96 compliant tags.

- Apply tags in specified label zones.

- Submit encoded EPCs through ASN (Advanced Shipping Notices).

12. Troubleshooting Encoding Issues

|

Problem |

Cause |

Solution |

|

Tags not encoding |

Printer antenna misalignment |

Calibrate printer, adjust label placement |

|

Unreadable tags |

Low-quality tags or interference |

Use high-quality tags, test read range |

|

Duplicate EPCs |

Serial number overlap |

Implement centralized serial management |

|

EPC doesn’t match barcode |

Software desync |

Sync print and encoding templates |

|

High tag failure rate |

Damaged inlay or faulty printer |

Perform diagnostics, switch suppliers if needed |

13. Future-Proofing Encoding System

- Adopt EPCIS (EPC Information Services) for event tracking.

- Integrate with blockchain for tamper-proof serialization.

- Utilize cloud-based EPC management for scalability.

- Support next-gen RFID Tags like the Impinj series.

- Automate encoding stations for high-speed fulfillment.

Conclusion

Proper RFID label encoding is not just a technical step; it is the very backbone of a successful RFID deployment in retail. From accurate inventory visibility and loss prevention to smooth supply chain integration and compliance with industry mandates, encoding determines how effectively you can leverage RFID’s full potential.

By understanding the standards, using the right hardware and software, implementing robust encoding processes, and adhering to best practices, you ensure that every RFID tag not only works but adds meaningful value to your retail operations.

Recent Posts

-

How RFID Handheld Readers Can Be Used with GPS for Asset Location Tracking

Asset tracking has become a critical challenge across industries such as logistics, warehousing, hea …Feb 26th 2026 -

How to Choose the Best RFID Printer: A Complete Buyer's Guide

1. What is an RFID Printer (and Why Do You Need One)? An RFID (Radio Frequency Identification) print …Feb 17th 2026 -

Zebra RFD40-M Premium Plus UHF RFID Sled

The Zebra RFD40M Premium Plus UHF RFID Sled is a modular, high-performance RFID reader that attaches …Feb 9th 2026