Zebra FXR90 Ultra-Rugged Fixed RFID Readers: The Definitive Guide

Fixed RFID readers are the backbone of many automated identification and data capture (AIDC) systems. Unlike handheld readers, these devices are installed in a fixed position—typically mounted at doors, dock doors, conveyor lines, gates, or checkpoints—and automatically read RFID tags as they pass by. They are essential in high-volume environments where tracking efficiency, automation, and real-time visibility are critical.

The FXR90 Ultra-Rugged Fixed RFID Reader is designed for environments where failure is not an option: cold storage, manufacturing plants, outdoor logistics yards, ports, and oil and gas operations. This article explores every aspect of the FXR90, equipping you with the insights needed to understand, deploy, and maximize this powerful reader.

Overview of the FXR90 Series

Zebra FXR90 is part of a next-generation class of industrial RFID readers designed for ultra-durability and performance. It's not just a reader—it’s an industrial-grade computing platform that withstands harsh elements and handles large volumes of tag reads with precision.

Key Points:

- Developed for mission-critical, ruggedized applications.

- Supports UHF (ultra-high frequency) passive RFID tags compliant with EPCglobal Gen 2v2 / ISO 18000-63 standards.

- Incorporates the latest edge processing technologies.

- Designed for easy integration into enterprise software ecosystems.

Purpose-Built for Harsh Environments

The FXR90 thrives where traditional readers fail. Whether exposed to dust storms, vibrations, extreme heat, or sub-zero temperatures, this reader is engineered to continue operating at peak efficiency.

Key Features of the FXR90

The FXR90 boasts a robust suite of features, making it suitable for industrial-grade RFID deployments.

1. Ultra-Rugged Housing

- IP67-rated enclosure for protection against water and dust ingress.

- Withstands shock, vibration, and impact.

- MIL-STD-810G compliance for military-grade durability.

2. High-Performance RF Engine

- Support for up to 4 external antennas with an integrated antenna. Without an integrated antenna, it supports 4 and 8 external antennas.

- Monostatic or bistatic antenna modes.

- High read sensitivity and long-range capability (~30+ feet depending on tags and environment).

- Dense reader mode (DRM) support for operating in crowded RF environments.

3. Edge Processing Capabilities

- Embedded Linux OS or optional Windows IoT Core.

- Built-in ARM or x86 processors (varies by configuration).

- Onboard memory and storage for local data processing.

- Advanced filtering, tag de-duplication, and event handling.

4. Connectivity with the FXR90 Fixed reader

- It is connected with Gigabit Ethernet, Wi-Fi, Bluetooth, Serial (RS-232), and USB.

- PoE+ support for power and data over a single cable.

- Optional cellular/LTE module for remote sites.

5. Advanced Security Features of Zebra FXR90

- Secure boot and encrypted firmware.

- 802.1X network authentication.

- Support for TLS/SSL, VPN, and remote management.

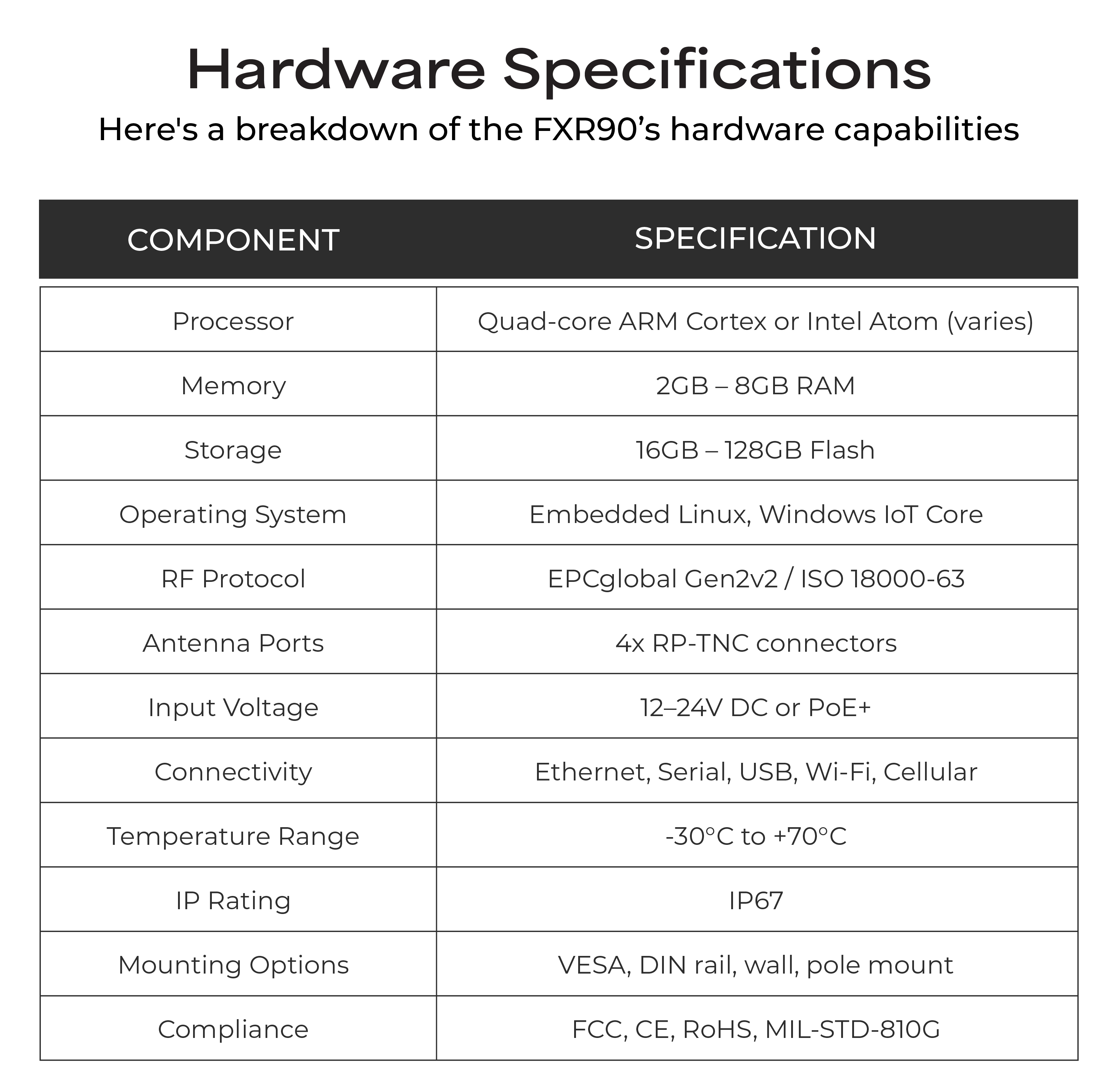

Hardware Specifications of ZebraFXR90

FXR90’s hardware capabilities:

Environmental Ruggedness & Industrial Design

Ruggedness is a defining trait of the FXR90. Unlike many readers that require protective enclosures, the FXR90 is natively engineered to endure.

- Dust and Debris: Sealed against particles found in mines and manufacturing plants.

- Water and Humidity: Fully submersible up to 1 meter (IP67).

- Temperature Extremes: Functions in extreme cold (cold storage) and intense heat (steel mills).

- Shock and Vibration: Engineered with rugged mounting brackets and vibration isolation.

- UV and Corrosion Resistance: Optional coatings for saltwater or outdoor use.

Its industrial design supports maintenance-free operation for years, even in remote or hostile environments.

Performance Capabilities

The FXR90 offers leading-edge performance for demanding applications:

- Read Rate: Over 1,200 RFID tag reads per second, depending on the environment.

- Read Range: Up to 10 meters (33 feet), depending on tag and antenna environment.

- Tag Density: Handles thousands of tags simultaneously with intelligent filtering.

- Latency: Sub-100-ms tag detection and event transmission.

With edge computing, it can also locally store and process tag reads, reducing backhaul traffic and enabling autonomous decision-making.

Installation and Deployment Scenarios

FXR90 is suitable for multiple industrial scenarios:

Dock Door Monitoring

Detects pallets or cartons passing through loading docks. Can be configured with motion sensors and light stacks for instant alerts.

Conveyor Belt Integration

It reads tags as items move along production lines, which is ideal for WIP tracking in factories.

Yard Management

Mounted at gates or checkpoints, the FXR90 identifies vehicles, containers, or high-value assets entering and exiting.

Cold Chain and Freezers

Performs reliably in sub-zero environments, essential for pharmaceutical and food logistics.

Hazardous Environments

Certified for use in explosive atmospheres (FXR90-EX variant), ideal for petrochemical plants and oil rigs.

Integration with RFID Middleware and Software

The FXR90 supports modern integration methods:

The FXR90 was designed to connect seamlessly with modern and legacy infrastructure.

- Ethernet/IP for industrial PLCs

- REST APIs and MQTT for IoT and cloud applications

- Serial and GPIO for sensor and actuator control

- Docker and Edge SDKs for deploying custom logic and applications

- It also supports RFID middleware

Use Cases Across Industries

- Use Cases Across Industries

Logistics and Distribution

- Automated shipment verification

- Trailer and dock door monitoring

- Real-time inventory updates

Manufacturing

- Work-in-progress (WIP) tracking

- Tool and part location monitoring

Assembly line automation

- Retail and Apparel

- Inventory receiving and dispatch portals

High-volume return processing

Healthcare and Pharmaceuticals

Cold chain verification

Medical equipment tracking

Defense and Government

Asset accountability

Secure area entry/exit monitoring

Oil & Gas

- Asset tracking on rigs

- Toolchain monitoring

- Explosive-zone operations

Retail Distribution Centers

- Goods-in/goods-out automation

- Loss prevention

- High-value item tracking

Security of the FXR90 reader

- End-to-End Encryption of Data in Transit

All data sent between the FXR90 reader and connected systems (such as cloud platforms or local servers) is encrypted using secure protocols like TLS (Transport Layer Security). This ensures that sensitive data, such as asset IDs, timestamps, and location metadata, is protected from interception or tampering during transmission. - Secure Boot and Signed Firmware Updates

The FXR90 uses secure boot to ensure that only authentic, manufacturer-approved firmware runs on the device. This protects against malicious code execution. Signed firmware updates ensure that any new software installed on the reader is cryptographically verified, preventing unauthorized or corrupted updates. - Multi-Factor Authentication (MFA) for Management Consoles

Access to the device’s configuration interface or remote management portal is protected with multi-factor authentication, typically combining a password with a secondary verification method (such as a mobile app or hardware token). This greatly reduces the risk of unauthorized access.

Compliance of the FXR90 reader

- Certified for Major Global Markets

The FXR90 meets regulatory standards in key markets (e.g., FCC in the U.S., CE in Europe, and others), ensuring it can be legally and safely deployed in many countries. This also validates that the reader performs well and adheres to radio frequency and safety regulations. - Optional ATEX/IECEx-Rated Enclosures

For use in hazardous environments—like oil refineries, chemical plants, or mining sites—the FXR90 can be housed in ATEX and IECEx-certified enclosures. These certifications ensure the device won’t ignite flammable gases or dust, making it safe for explosive atmospheres. - RoHS and WEEE Compliant

The FXR90 adheres to RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives, which limit harmful substances in electronics and mandate proper end-of-life disposal and recycling.

Maintenance of the FXR90 reader

- Remote Diagnostics and Firmware Updates

Administrators can remotely check the health and status of the reader, diagnose issues, and push firmware updates without needing to be on-site. This minimizes downtime and simplifies system-wide upgrades. - Built-in Self-Health Monitoring

The FXR90 continuously monitors its own performance metrics—like temperature, voltage levels, and connectivity status. If any anomaly is detected, it can log the issue or notify the system administrator automatically. - Predictive Failure Alerts via Integration with Cloud Platforms

When connected to a cloud-based platform, the FXR90 can analyze trends in performance data to detect early signs of component wear or failure. This allows for predictive maintenance, where issues are resolved before causing system outages.

Future Trends and How the FXR90 Fits In

The future of industrial RFID readers involves:

- Greater edge computing integration

- AI-based anomaly detection and predictive analytics

- Unified device and sensor platforms (IoT + RFID + Vision)

- 5G and private LTE for mobile deployments

The FXR90 is well-positioned to adapt to these trends thanks to its computing power, modularity, and open platform support.

Final Thoughts

The FXR90 Ultra-Rugged Fixed RFID Reader is more than just a data collection device—it's a resilient, intelligent, and integrative edge platform that drives automation and visibility in the harshest industrial conditions. With its robust construction, edge intelligence, versatile connectivity, and security-first design, the FXR90 redefines what's possible in fixed RFID deployments.

Whether you're deploying it in a freezing warehouse, a scorching manufacturing plant, or an explosive oil rig environment, the FXR90 is a future-proof investment that delivers performance, durability, and peace of mind.

Recent Posts

-

Impinj R700 UHF RFID Reader: Comprehensive Guide

The Impinj R700 UHF RFID reader represents a significant advancement in fixed RFID reading technolog …May 26th 2025 -

RFD40 UHF RFID Sled: A Comprehensive Overview

In today’s fast-paced retail, logistics, healthcare, and warehousing environments, the need fo …May 20th 2025 -

Zebra FXR90 Ultra-Rugged Fixed RFID Readers: The Definitive Guide

Fixed RFID readers are the backbone of many automated identification and data capture (AIDC) systems …May 12th 2025