RFID Portals vs. Handhelds: Which Is Better?

Radio Frequency Identification (RFID) technology has revolutionized asset tracking, inventory management, and logistics. Companies across industries—from retail and manufacturing to healthcare and aerospace—are embracing RFID to gain real-time visibility into their operations.

Two primary types of RFID reading systems dominate the conversation: RFID portals and handheld RFID readers. Each offers distinct advantages and potential drawbacks depending on the environment, the use case, and the operational scale.

Choosing between RFID portals and handhelds is a strategic decision that impacts workflow efficiency, accuracy, scalability, and total cost of ownership. This comprehensive article will guide you through the strengths, limitations, and ideal applications of each system, helping you determine the best fit for your business.

What Are RFID Portals?

An RFID portal is a fixed system that automatically reads RFID tags as they pass through a designated checkpoint. Typically installed around doorways, warehouse dock doors, conveyors, or entrances, portals consist of multiple RFID antennas and readers enclosed in a physical frame.

When tagged items or pallets move through the portal, the system automatically captures their data without human intervention. RFID portals often integrate with backend RFID software platforms to instantly update inventory systems, trigger alerts, or initiate workflows.

Key Characteristics of RFID Portals:

- Fixed location: Installed permanently at strategic points.

- Hands-free: No manual scanning required.

- High throughput: Designed to read many tags quickly.

- Automation: Integrated with broader IT and operational systems.

What Are RFID Handhelds?

An RFID handheld reader is a portable, battery-powered device that combines an RFID antenna, reader module, and often a barcode scanner into one unit. Operators carry handhelds and actively scan RFID tags on assets, inventory, or shipments.

Handhelds are highly versatile and offer flexibility in environments where fixed infrastructure isn’t feasible or cost-effective. They can be paired with mobile apps or backend systems for data upload and analysis.

Key Characteristics of RFID Handhelds:

- Portable: Carried by users for spot-checks, audits, and item searches.

- User-driven: Manual scanning is required.

- Flexible: Can be used across multiple locations.

- Lower infrastructure cost: No need for large installations.

Advantages of RFID Portals

1. Hands-Free Operation

RFID portals automate the scanning process. Once installed, items are read automatically as they pass through. This removes the need for dedicated scanning personnel, reducing labor costs and human error.

2. High Volume Tag Reading

Portals excel at reading hundreds or even thousands of tags simultaneously, making them ideal for environments like warehouse receiving docks or manufacturing production lines where large volumes need processing quickly.

3. Integration with Business Systems

Portals often link directly to ERP, WMS (Warehouse Management Systems), or asset management platforms. Real-time data updates lead to faster decision-making, accurate inventory counts, and seamless workflow automation.

4. Streamlined Workflows

Because they operate automatically, portals support faster processes—like shipment verification, returns processing, or production tracking—without slowing down operations.

5. Improved Accuracy

By removing manual steps, portals reduce scanning errors and missed reads. They enforce process compliance automatically (e.g., ensuring every pallet is read before entering storage).

Limitations of RFID Portals

1. High Upfront Costs

Installing RFID portals involves significant expenses, including hardware, software, cabling, power supply, mounting infrastructure, and professional installation services.

2. Fixed Location Limitations

Once installed, a portal cannot be easily relocated. If your workflows change or if you move operations, the investment might not remain viable without additional infrastructure spending.

3. Environmental Constraints

Some environments—such as outdoor locations, areas with high metal interference, or highly congested spaces—can pose challenges to portal installation and reliable tag reading.

4. Maintenance Requirements

Like any fixed infrastructure, portals require periodic maintenance, calibration, and sometimes environmental adjustments (e.g., shielding against RF interference).

- High Density

For the RFID Portal, it is hard to read the RFID tags if the density of the RFID tags is large.

Advantages of RFID Handhelds

1. Flexibility and Mobility

Handheld readers can go wherever your team needs them—different warehouses, multiple retail stores, on the shop floor, or even out in the field. This mobility is crucial for businesses with dynamic or multi-site operations.

2. Lower Initial Investment

Handhelds involve significantly lower upfront costs compared to portals. You simply purchase the handheld device, possibly some supporting RFID software, and minimal accessories.

3. Versatile Use Cases

Handhelds can be used for:

- Spot-checking inventory

- Locating specific items

- Cycle counting

- Auditing shipments

- Managing retail stock

- Field service asset tracking

This versatility makes them popular across a wide range of industries.

4. User Control

Operators can decide exactly which assets to scan and when, adding a layer of operational control that is difficult to achieve with fully automated portals.

5. Easier Deployment

Setting up handheld systems is quicker and simpler. You don't need to install heavy infrastructure or run power and network cabling.

Limitations of RFID Handhelds

1. Labor-Intensive

Since handhelds require manual operation, processes can be slower and dependent on human availability and diligence. Mistakes or omissions are possible.

2. Limited Throughput

Handhelds are not suitable for environments requiring mass, continuous tag reading at high speeds (e.g., busy dock doors processing hundreds of pallets per hour).

3. Battery Life and Durability

Handhelds require regular charging and are subject to physical wear and tear. Devices can be dropped, lost, or damaged, requiring ongoing attention to hardware maintenance.

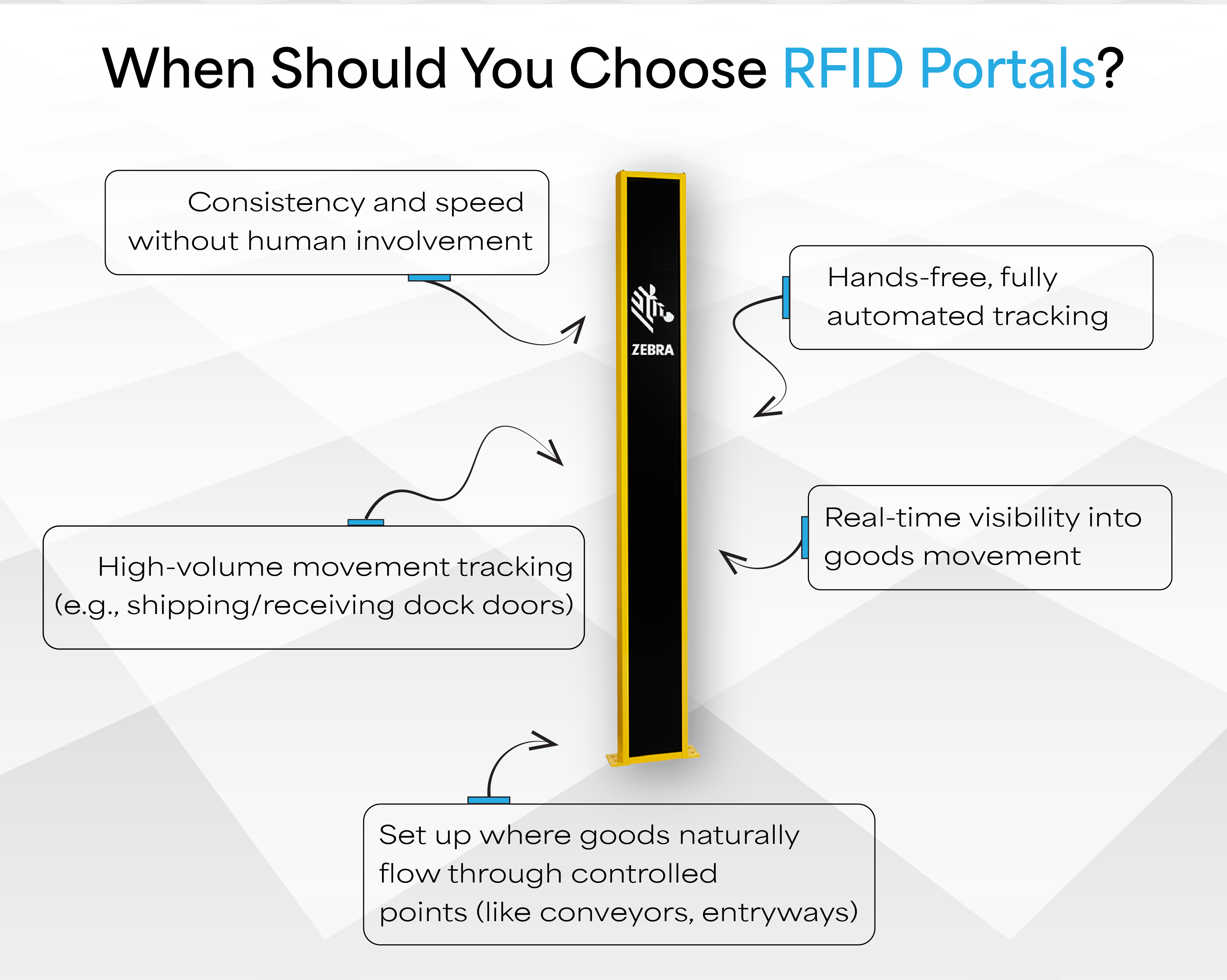

When to Choose RFID Portals

1. High-Volume, High-Speed Environments

If your operation needs to track thousands of items per day—especially in logistics, distribution centers, or manufacturing—portals are the best choice.

Example: A busy warehouse that receives 200 pallets daily can automate receiving with portals, updating inventory instantly.

2. Automated Compliance and Auditing

Portals help enforce business rules automatically. For example, ensuring that every outgoing shipment is verified without manual checks.

3. Process Standardization

If you require a uniform, reliable process with minimal human variation, portals deliver more consistent results.

4. Restricted Access Monitoring

Portals installed at exits can monitor unauthorized asset movement, aiding in loss prevention or sensitive equipment security.

When to Choose RFID Handhelds

1. Small to Mid-Sized Operations

For businesses handling fewer tagged items per day, handhelds are more cost-effective and practical.

Example: A small retail store uses a handheld reader to cycle-count inventory weekly.

2. Field Service or Remote Locations

Handhelds shine when fixed infrastructure is impractical, such as remote warehouses, construction sites, or outdoor events.

3. Budget-Conscious Projects

Organizations starting out with RFID or those with limited budgets often begin with handhelds and scale up later.

4. Flexible or Changing Workflows

If your workflows evolve rapidly, handhelds offer the agility to adjust without heavy reinvestments.

Hybrid Approaches: Combining Portals and Handhelds

Many organizations find that the best solution is not either/or—but both.

For example:

- Portals handle high-volume, high-velocity operations at dock doors.

- Handhelds are used for auditing, error-checking, or locating specific items on the floor.

Hybrid RFID strategies maximize the strengths of both systems, offering broad coverage, flexibility, and operational efficiency.

Key Factors to Consider Before Choosing

Before making a decision, analyze these factors:

|

Factor |

RFID Portals |

RFID Handhelds |

|

Volume of Items |

High |

Low to Medium |

|

Budget |

Higher upfront cost |

Lower upfront cost |

|

Flexibility Needed |

Low (fixed locations) |

High (mobile use) |

|

Space Constraints |

Needs clear defined space |

Minimal |

|

Deployment Speed |

Longer setup time |

Quick setup |

|

Labor Involvement |

Minimal |

High |

|

Maintenance Needs |

Moderate to High |

Low to Moderate |

|

Environment Stability |

Indoor, controlled |

Versatile, indoor/outdoor |

|

Future Scalability |

Excellent for large scale |

Good for dynamic scale |

Real-World Industry Examples

Retail Industry

- Portals: Used at stockroom entrances to track goods entering/exiting automatically.

- Handhelds: Used by staff for quick inventory checks and in-store item locating.

Logistics and Warehousing

- Portals: Installed at dock doors for inbound and outbound shipment verification.

- Handhelds: Used for returns processing and random audits.

Manufacturing

- Portals: Track Work-In-Progress (WIP) through production stages.

- Handhelds: Conduct equipment audits or quality inspections.

Healthcare

- Portals: Monitor movement of critical medical equipment.

- Handhelds: Track patient files, medicine, or mobile assets on demand.

Conclusion: RFID Portals vs. Handhelds – Which Is Better for You?

There is no one-size-fits-all answer.

- If you need high-speed, automated, hands-free scanning at specific checkpoints with minimal labor, RFID portals are your ideal solution.

- If you prioritize flexibility, mobility, and lower investment, RFID handhelds are the smarter choice.

- And if your environment demands the best of both worlds, a hybrid approach will future-proof your operations.

There’s no universal "best" option — it depends entirely on your needs.

Ask yourself:

- How much automation do I need?

- How large is my operation?

- Where are the key tracking points?

- How important is real-time data?

- What's my budget (now and in the future)?

Ultimately, your business goals, budget, operational style, and growth plans should drive the decision. Investing in the right RFID infrastructure today can unleash efficiencies, cost savings, and competitive advantages for years to come.

Recent Posts

-

RFID Gate Portals in Retail and Warehouses

The landscape of retail and warehouse operations is undergoing a profound transformation, moving awa …Dec 18th 2025 -

Why Add RFID to Your Labeling Strategy in 2026

In 2026, the global supply chain is undergoing a seismic transformation. From omnichannel retail to …Dec 11th 2025 -

Zebra Handheld RFID Readers for Retail Efficiency

In the dynamic world of retail, where inventory accuracy, customer experience, and operational effic …Nov 28th 2025