Washable RFID Tags for Laundry and Textiles

The laundry and textile industry — covering everything from commercial laundries and hospitals to hotels, uniform services, and industrial textile management — faces a unique challenge: tracking thousands (or even millions) of individual textile items through repeated wash cycles, heat exposure, chemicals, and handling.

Traditional tracking methods such as manual counting, barcodes, or handwritten logs are inefficient, prone to errors, and slow. Enter Washable RFID Tags — specialized UHF RFID transponders designed to withstand harsh laundry processes while enabling automated, accurate, and real-time tracking of textile items.

These tags have revolutionized how businesses manage inventory, asset lifespan, and operational efficiency in textile-heavy industries.

1. What Are Washable RFID Tags?

Washable RFID tags are durable, water-resistant, and heat-tolerant RFID tags engineered for textile applications. They are built to survive:

- High-temperature wash cycles

- Aggressive detergents and bleaching chemicals

- Drying and ironing at high heat

- Mechanical stress from folding, pressing, and handling

Key Technical Features of Washable RFID Tags

- Encapsulation: Sealed in a waterproof, chemical-resistant housing (polyester, epoxy resin, or silicone)

- Frequency: UHF (860–960 MHz)—Suitable for bulk scanning and faster inventory processes

- Read Range: UHF: Typically 1–6 meters (depending on reader, antenna, and environment)

- Memory: User and EPC memory for storing unique IDs and optional item data

- Lifespan: 200–500+ wash cycles, depending on design and brand.

Key Technical Features of Washable RFID Tags

2. Why Use Washable RFID Tags in Laundry & Textile Management?

Key Benefits of Washable RFID Tags

a. Automated Tracking

No need for manual scanning — RFID readers can identify multiple tagged items in bulk.

b. Improved Accuracy

- Reduces counting errors

- Minimizes losses and misplacements

c. Increased Operational Efficiency

- Faster sorting and dispatching

- Better workflow in high-volume laundry facilities

d. Asset Life Monitoring

Tracks how many washes each item has gone through to predict replacement schedules. We can use TagMatiks AT Lite and TagMatiks AT for asset tracking.

e. Loss Prevention

Alerts when items are missing or moved to the wrong location.

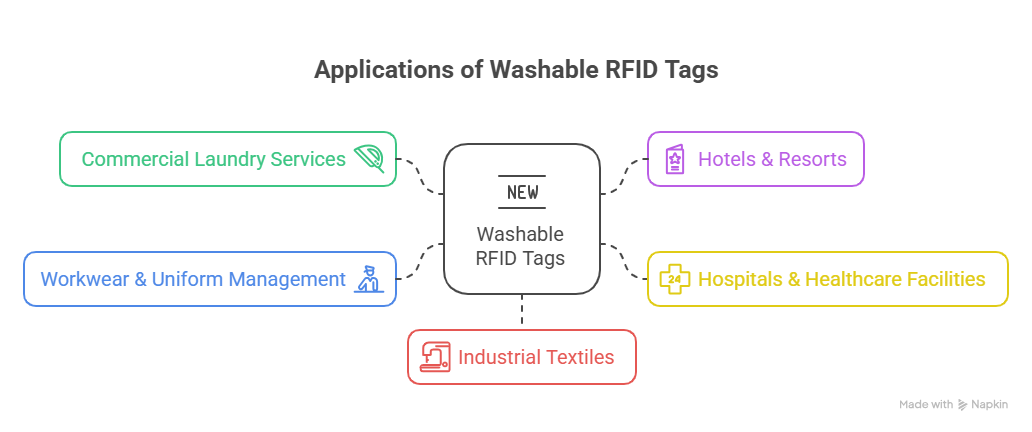

3. Applications of Washable RFID Tags

a. Commercial Laundry Services

- Track customer-owned textiles separately

- Prevent mix-ups between clients

b. Hotels & Resorts

- Monitor linen stock across rooms and laundry facilities

- Reduce theft or loss of towels, robes, and sheets

c. Hospitals & Healthcare Facilities

- Track patient gowns, bedsheets, surgical drapes, and uniforms

- Ensure hygiene compliance by recording wash cycles

d. Workwear & Uniform Management

- Assign uniforms to employees and monitor usage

- Track laundering frequency for safety and hygiene standards

e. Industrial Textiles

- Monitor heavy-duty textile items (filters, safety gear) that go through industrial washing

4. Design and Construction of Washable RFID Tags

a. Form Factors

- Sew-In Tags: Polyester or fabric-encased, stitched into seams or hems

- Pouch Tags: Inserted into a pocket, sewn onto the textile

- Button Tags: Hard plastic disc-like tags sewn or riveted onto textiles

- Heat-Sealable Tags: Attached using a heat press or adhesive bonding

b. Durability Requirements

- Waterproof rating (IP68 or higher preferred)

- Resistance to chlorine bleach and detergents

- Thermal endurance up to 180°C (for ironing and pressing)

- Mechanical robustness for tumbling and folding

5. Technical Specifications to Look For: washable RFID tag

When selecting washable RFID tags, key parameters include

|

Specification |

Typical Range |

Why It Matters |

|

Operating Frequency |

UHF (860–960 MHz) |

Determines read range and compatibility |

|

Memory Size |

96–512 bits EPC, optional user memory |

For storing unique IDs or extra data |

|

Read Range |

UHF: 1–6 m |

Impacts scanning speed and distance |

|

Wash Cycle Resistance |

200–500+ |

Indicates durability and lifespan |

|

Heat Resistance |

Up to 180°C |

Ensures survival in drying/ironing |

|

Chemical Resistance |

High |

Withstands detergents and bleach |

|

Attachment Method |

Sew-in, heat seal, rivet, pouch |

Impacts installation time and durability |

6. Implementation Process

Step 1: Needs Assessment

- Identify textile types, volumes, and turnover rates

- Decide on UHF based on scanning needs

Step 2: RFID Tag Selection

- Match tag durability with your laundry process

- Select the proper form factor (sew-in, heat-sealed, button)

Step 3: Software Integration

- Use RFID asset tracking software compatible with laundry operations. Use RFID software, TagMatiks AT Lite, for tracking the different types of laundry.

- Ensure it supports bulk scanning, wash cycle tracking, and client segregation

Step 4: Reader Setup

- Install RFID handheld readers for spot checks

- Deploy RFID fixed readers at key points (sorting, washing, entry/exit, dispatch)

Step 5: Staff Training

- Teach proper tag placement and scanning procedures

- Train on software usage for real-time updates

7. Maintenance and Best Practices

- Inspect tags periodically for damage

- Avoid folding textiles over tags in high-pressure pressing machines

- Store extra tags for replacement needs

- Maintain a clean database by retiring damaged or unreadable tags

8. Challenges and Considerations

- RFID Interference: Metal trolleys or wet environments can affect the read range

- Tag Loss: Improper attachment may cause tags to detach during washing

Conclusion

Washable RFID tags have transformed laundry and textile management by enabling automation, accuracy, and efficiency even in the harshest washing conditions. Whether you operate a hotel, hospital, industrial laundry, or uniform service, selecting the right tag type, frequency, and durability ensures a strong ROI and long-term benefits.

When choosing a solution, balance technical specifications, operational needs, and integration capabilities to ensure a seamless implementation that works for your unique environment.

Recent Posts

-

How RFID Handheld Readers Can Be Used with GPS for Asset Location Tracking

Asset tracking has become a critical challenge across industries such as logistics, warehousing, hea …Feb 26th 2026 -

How to Choose the Best RFID Printer: A Complete Buyer's Guide

1. What is an RFID Printer (and Why Do You Need One)? An RFID (Radio Frequency Identification) print …Feb 17th 2026 -

Zebra RFD40-M Premium Plus UHF RFID Sled

The Zebra RFD40M Premium Plus UHF RFID Sled is a modular, high-performance RFID reader that attaches …Feb 9th 2026