Rugged RFID Readers: Built for Harsh Industrial Environments

Radio Frequency Identification (RFID) technology has become a cornerstone in industries that require real-time tracking, asset management, and automation. From manufacturing and logistics to mining and oil & gas, RFID solutions improve visibility, reduce losses, and streamline operations. However, not all workplaces are clean, controlled, and technology-friendly. Many industries operate in harsh, rugged, and unpredictable environments where dust, water, extreme temperatures, and physical impact are part of daily operations.

In such conditions, standard RFID readers often fail, leading to downtime, inefficiencies, and costly equipment replacements. This is where rugged RFID readers come in — purpose-built devices engineered to withstand environmental stress without compromising on performance.

They are essential in demanding industries, and their features, use cases, and how businesses can choose the right one for their operations.

What Are Rugged RFID Readers?

A rugged RFID reader is a specialized device designed to read and write RFID tags in extreme and harsh environments. Unlike standard RFID readers, which are built for controlled indoor settings, rugged models feature:

- Reinforced housing for impact resistance

- Sealed casings to protect against dust and liquids

- Extended operating temperature ranges

- Shock and vibration resistance

- Long-lasting power options for field operations

They can be handheld, mounted, or integrated into fixed installations, depending on the use case. Rugged RFID readers are commonly used in outdoor, industrial, and mobile scenarios where durability is just as important as tag reading accuracy.

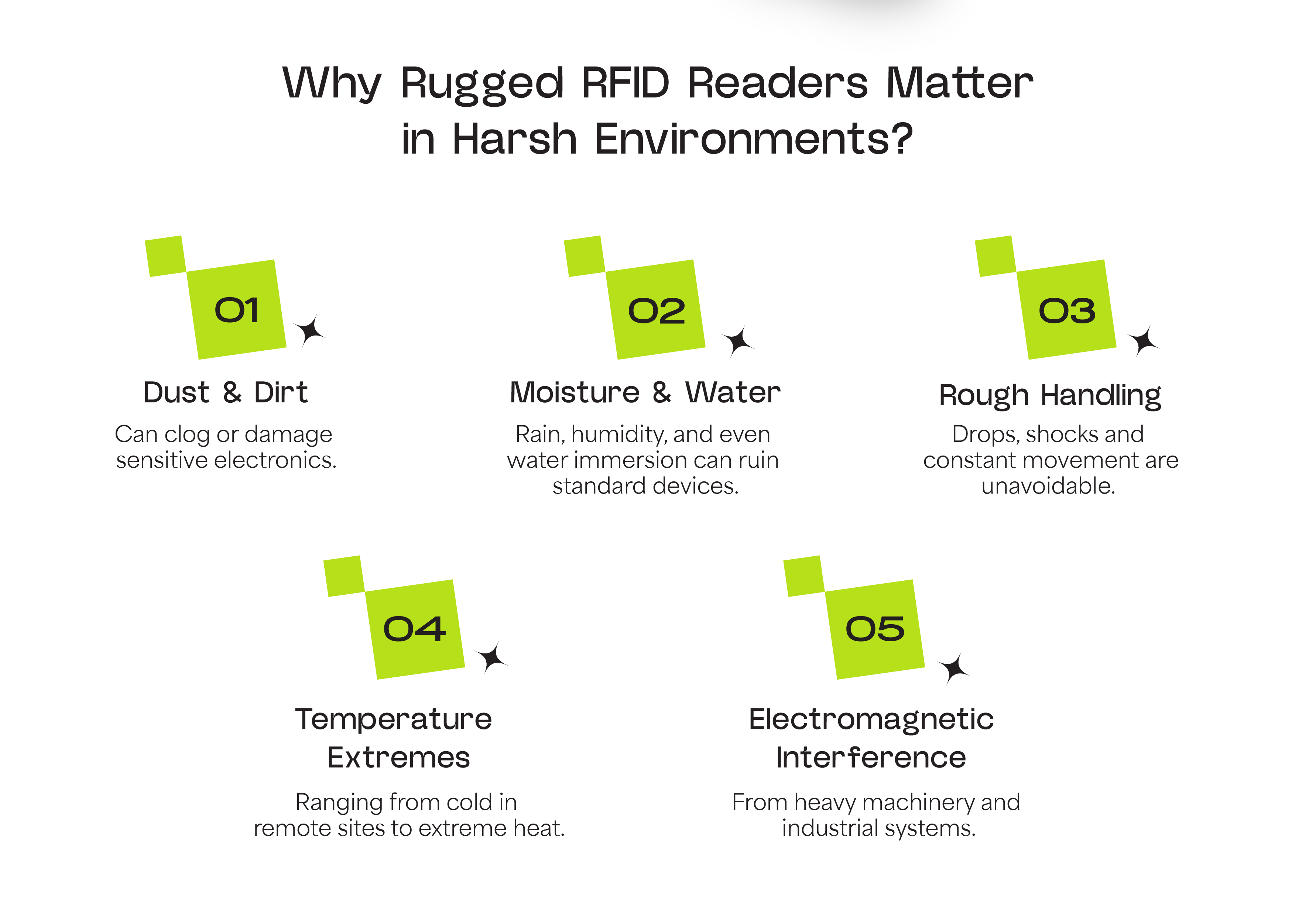

Why Rugged RFID Readers Matter in Harsh Environments

Industries like construction, mining, warehousing, transportation, oil and gas, utilities, and defense cannot rely on fragile technology. In these fields, equipment is often exposed to:

- Dust and Dirt: Can clog or damage sensitive electronics.

- Moisture and Water: Rain, humidity, and even immersion in water can ruin standard devices.

- Temperature Extremes: Ranging from freezing cold in remote sites to extreme heat in manufacturing plants.

- Rough Handling: Drops, shocks, and constant movement are unavoidable in high-activity environments.

- Electromagnetic Interference: From heavy machinery and industrial systems.

A rugged RFID reader ensures continuous performance regardless of these challenges, enabling businesses to maintain efficiency and avoid costly interruptions.

Key Features of Rugged RFID Readers

When evaluating rugged RFID readers, it’s important to look at specific features that set them apart from standard models:

1. Durability and Build Quality

- Designed with reinforced materials, such as hardened plastics, rubber bumpers, and metal framing.

- Drop-resistant from heights of 1.5 to 2 meters onto concrete.

2. Ingress Protection (IP) Rating

- IP65, IP67, or higher protection against dust and water.

- Withstands direct water spray or immersion without damage.

3. Operating Temperature Range

- Functional in extreme cold (-20°C) and extreme heat (+55°C or higher).

- Suitable for both freezer warehouses and desert oil fields.

4. Connectivity Options

- Wi-Fi, Bluetooth, LTE/5G, and USB for flexible communication.

- Seamless integration with enterprise systems and cloud platforms.

5. Power and Battery Life

- Extended battery performance for field workers.

- Hot-swappable batteries for non-stop operations.

6. High Read Performance

- Capable of reading hundreds of tags per second.

- Long read ranges (up to 20 meters or more with UHF readers).

7. Ergonomic Design

- Lightweight for handheld use despite ruggedness.

- Comfortable grips for extended use in field operations.

Types of Rugged RFID Readers

1. Handheld Rugged RFID Readers

Portable and mobile, ideal for field workers, inventory checks, and mobile asset tracking.

2. Fixed Rugged RFID Readers

Mounted in harsh environments such as outdoor yards, warehouses, and production lines for continuous monitoring.

3. Vehicle-Mounted Rugged RFID Readers

Integrated into forklifts, trucks, or heavy equipment to track goods in transit and streamline warehouse logistics.

4. Rugged RFID Sleds

Attachable devices that convert standard smartphones or tablets into rugged RFID readers with enterprise-grade durability.

Applications of Rugged RFID Readers in Harsh Environments

1. Mining and Oil & Gas

- Tracking equipment and tools in underground mines.

- Monitoring safety gear and workers in remote oil fields.

- Withstanding explosive environments with intrinsically safe designs.

2. Construction and Infrastructure

- Managing building materials across large outdoor sites.

- Tracking expensive tools and machinery.

- Ensuring compliance with safety regulations.

3. Logistics and Warehousing

- Operating in outdoor shipping yards and cold storage.

- Improving forklift operations with vehicle-mounted rugged readers.

- Handling goods in dust-heavy or moisture-prone facilities.

4. Utilities and Energy

- Tracking assets in power plants, wind farms, and solar facilities.

- Supporting field technicians with rugged handhelds for asset inspections.

5. Defense and Military

- Managing supply chains in extreme field conditions.

- Tracking equipment, vehicles, and personnel in hostile environments.

Benefits of Rugged RFID Readers

- Minimized Downtime: Continuous performance despite environmental challenges.

- Lower Total Cost of Ownership (TCO): Reduced replacements and repairs compared to standard readers.

- Increased Productivity: Workers spend less time troubleshooting devices and more time on tasks.

- Accurate Data in Real Time: Even in extreme environments, organizations can maintain high visibility.

- Regulatory Compliance: Particularly in industries like mining and oil where safety and traceability are mandatory.

How to Choose the Right Rugged RFID Reader

When selecting a rugged RFID reader, businesses should consider:

- Environment: Is it exposed to dust, moisture, temperature extremes, or heavy shocks?

- Form Factor: Handheld, fixed, vehicle-mounted, or sled?

- Tag Compatibility: Ensure support for UHF RFID tags as required.

- Connectivity: Does it integrate with existing systems (ERP, cloud)?

- Battery Performance: Is it suitable for extended shifts without interruption to charging?

- Budget and ROI: Consider long-term savings from durability and efficiency.

Conclusion

Rugged RFID readers are more than just durable devices — they are enablers of efficiency, safety, and reliability in industries where failure is not an option. By withstanding dust, water, shocks, and extreme temperatures, these readers ensure uninterrupted performance in the harshest conditions.

From mining to defense, rugged RFID readers are helping businesses track assets, improve productivity, and maintain operational excellence where traditional technology simply cannot survive. As industries continue to push into harsher and more remote environments, rugged RFID readers will play an increasingly critical role in ensuring success.

Recent Posts

-

How to Choose the Best RFID Printer: A Complete Buyer's Guide

1. What is an RFID Printer (and Why Do You Need One)? An RFID (Radio Frequency Identification) print …Feb 17th 2026 -

Zebra RFD40-M Premium Plus UHF RFID Sled

The Zebra RFD40M Premium Plus UHF RFID Sled is a modular, high-performance RFID reader that attaches …Feb 9th 2026 -

RFID Label Sizes & Formats Guide 2026

Radio Frequency Identification (RFID) labels are the backbone of modern asset tracking, inventory ma …Jan 23rd 2026