RFID Labels for Inventory: Formats, Adhesives & Durability GuideMeta Description

RFID labels may look simple on the surface, but they are engineered components that directly influence the accuracy, speed, and reliability of your entire inventory management system. The wrong label can cause misreads, premature failure, or operational bottlenecks. The right label, however, becomes a long-term asset—improving traceability, reducing labor, and ensuring consistent performance across diverse environments.

Below is a deeper, more comprehensive breakdown of the key factors to consider when selecting RFID labels for inventory applications.

RFID Label Formats: Matching Form to Function

RFID labels come in multiple constructions, each optimized for specific surfaces, read ranges, and application workflows. Understanding these formats helps you choose the right label for your operational needs.

RFID Label Components:

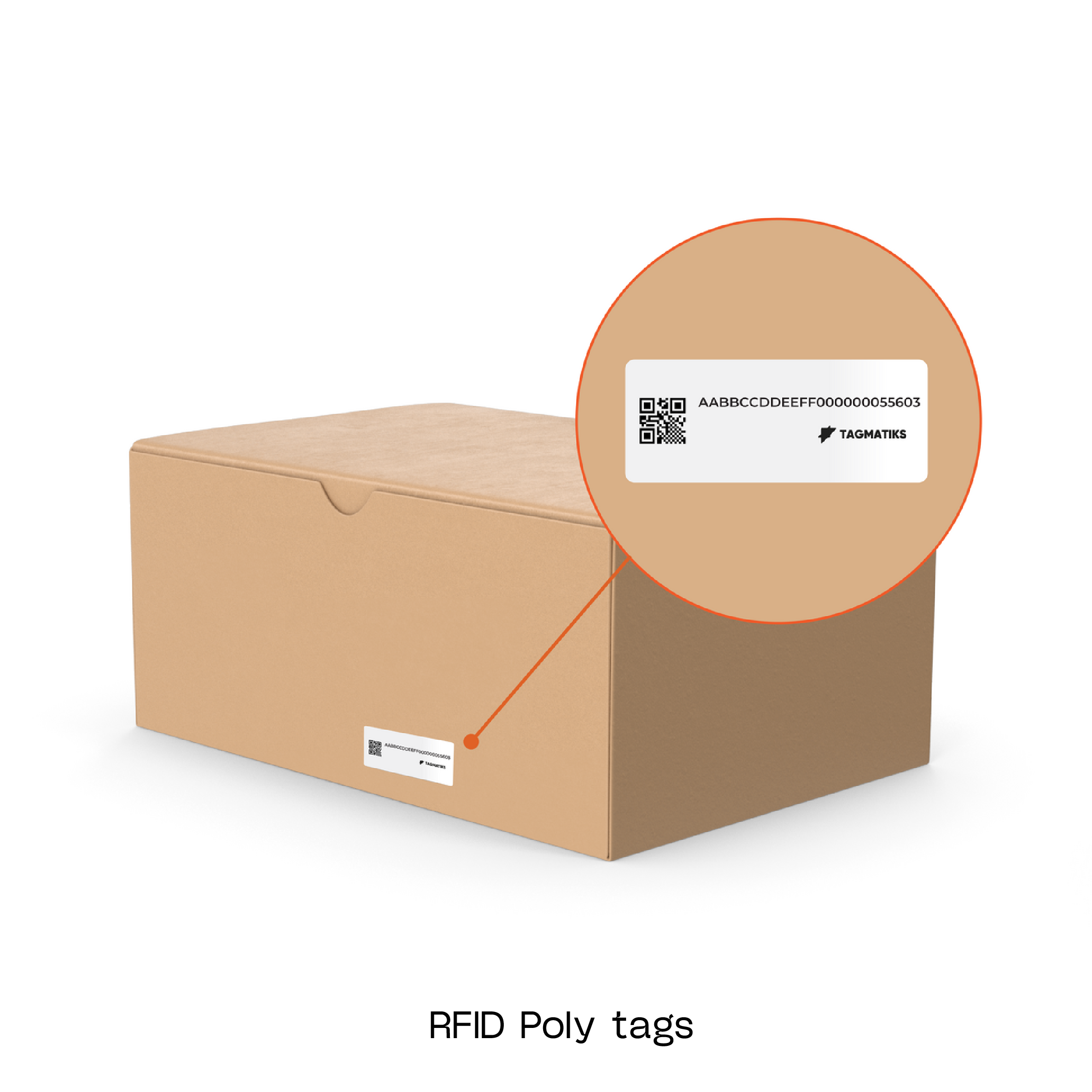

- Inlays

- Consists of an RFID chip + antenna on a thin substrate.

- Best for embedding into packaging, tickets, or custom label constructions.

- Ideal for high-volume, low-cost applications.

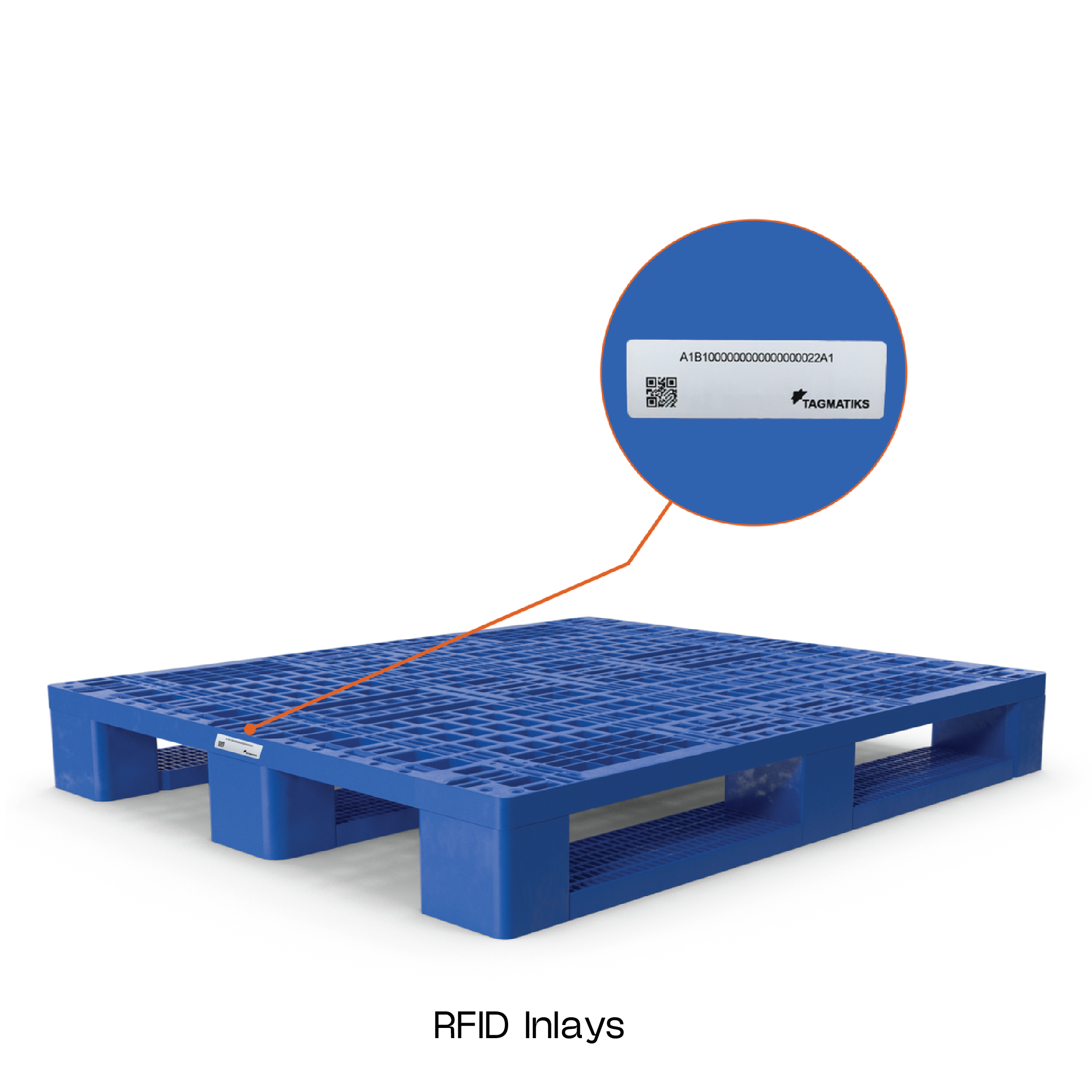

- Inlays with pressure-sensitive adhesive applied.

- Used by label converters to produce finished RFID labels.

- Great for automated application lines.

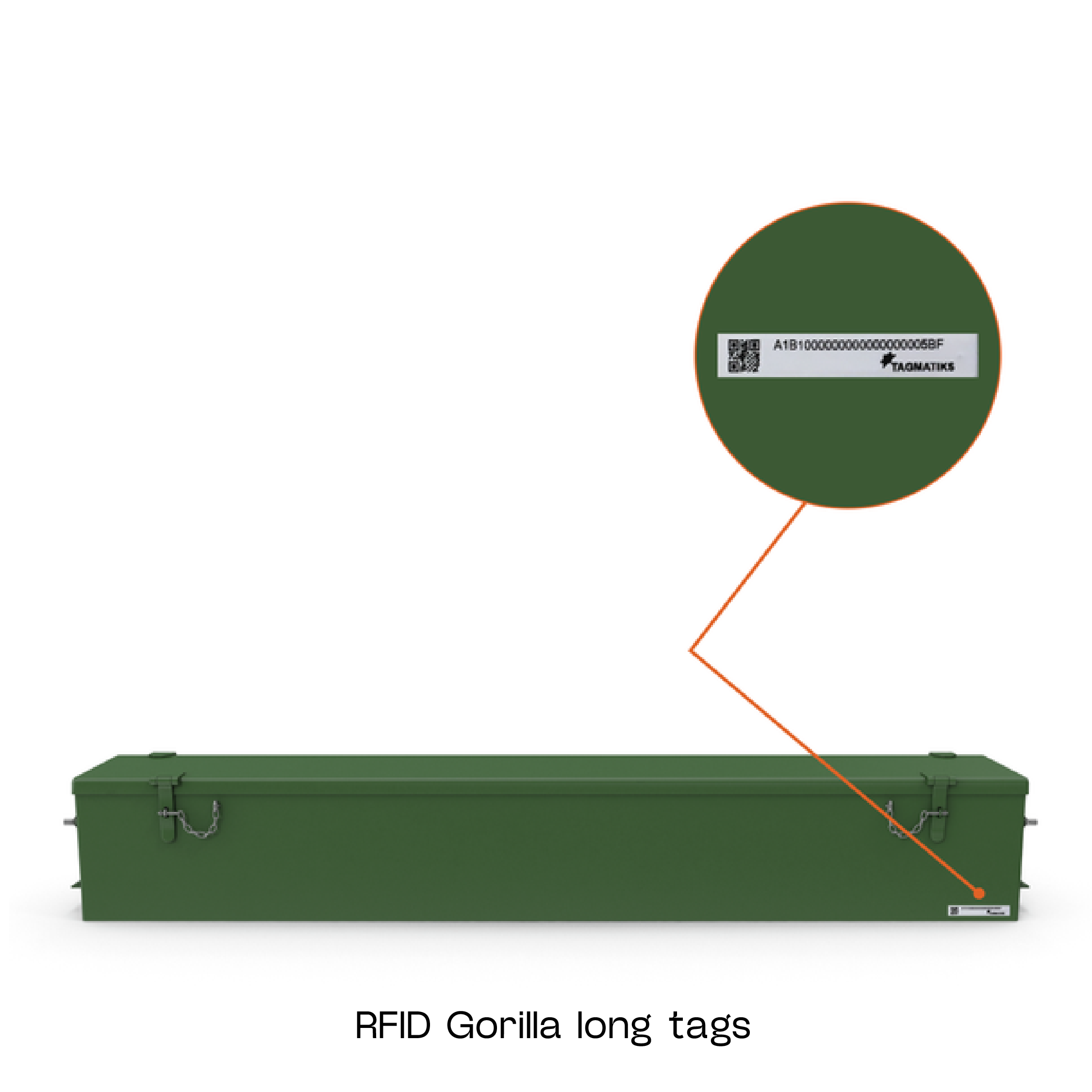

- Smart Labels (Finished RFID Labels)

- Fully converted labels with printing, encoding, and protective facestock.

- Can include barcodes, logos, and human-readable text.

- Ideal for retail, logistics, and asset tracking.

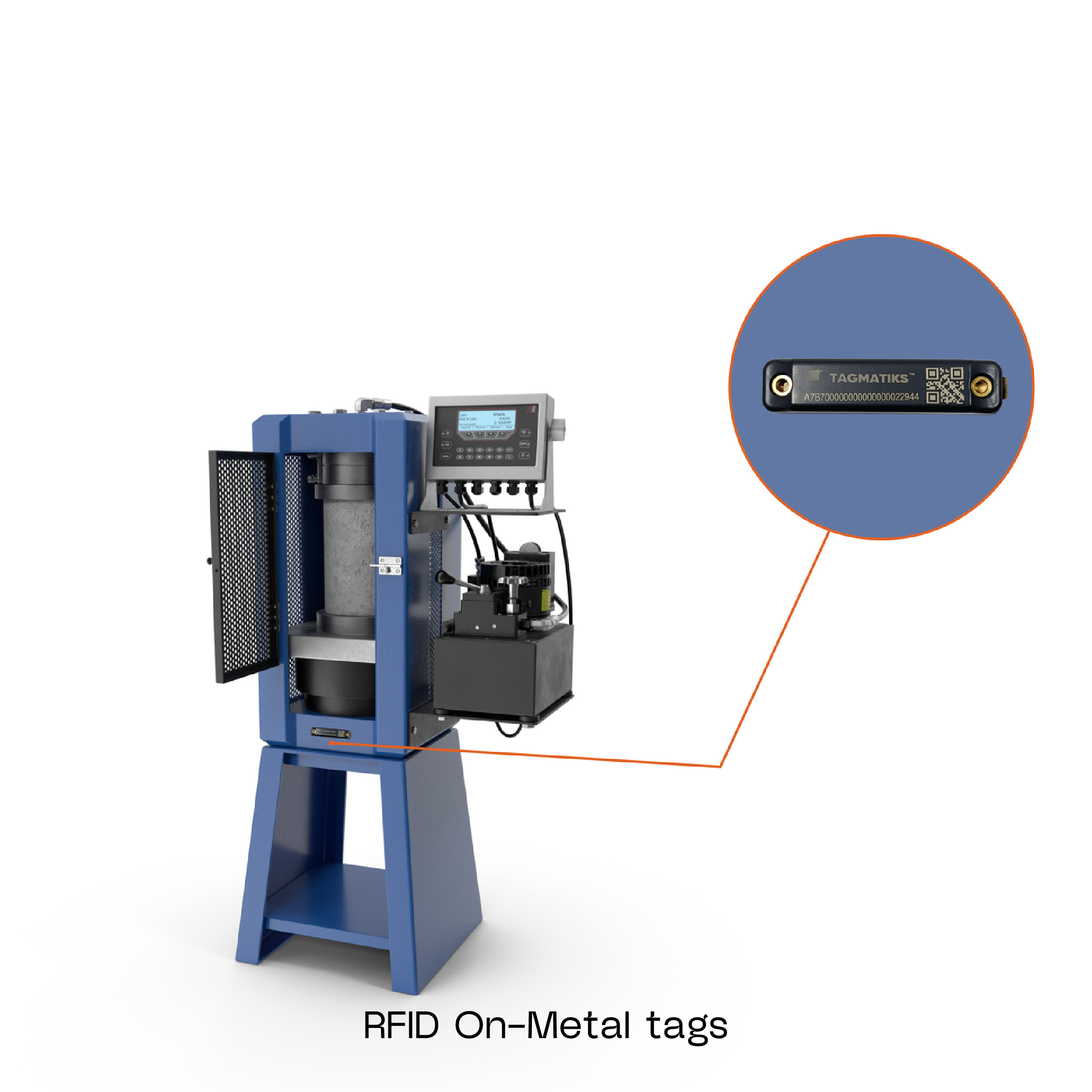

- On-Metal / Metal-Mount Labels

- Include ferrite or foam layers to prevent detuning on metal surfaces.

- Essential for tools, IT assets, machinery, and metal racks.

- Offer higher read reliability in RF-hostile environments.

Size & Antenna Considerations

- Larger antennas → longer read range, better sensitivity.

- Smaller antennas → shorter range but ideal for tight spaces.

- Curved surfaces require flexible labels or flag-style tags.

- Dense environments, liquids, or metals: may require specialized antenna designs.

Pro Insight:

Antenna geometry matters as much as size. For example, dipole antennas perform well in open-air environments, while folded or dual-dipole antennas excel near challenging materials.

Adhesive Types: Stick with the Right Bond

The adhesive determines whether your RFID label stays in place for days, months, or years. It must match the surface energy, texture, and environmental conditions.

Common Adhesive Types for an RFID Label

- Permanent Adhesives

Strong, long-lasting bond.

- Ideal for cardboard, plastic totes, metal surfaces (with on-metal labels).

- Used in warehouses, logistics, and long-term asset tagging.

- Removable Adhesives

- Peel off cleanly without residue.

- Perfect for temporary inventory, rental equipment, or reusable containers.

- High-Tack / Extra-Strength Adhesives

- Designed for low-surface-energy materials like polypropylene, rubber, or powder-coated metals.

- Excellent for industrial environments.

- Freezer-Grade Adhesives

- Maintain adhesion at sub-zero temperatures.

- Used in cold chain, pharmaceuticals, and frozen food storage.

- High-Temperature Adhesives

- Withstand exposure to heat, steam, or sterilization.

- Common in healthcare, electronics manufacturing, and automotive.

- Specialty Adhesives

- Chemical-resistant for harsh environments.

- Tamper-evident for security applications.

- Foam adhesives for uneven or rough surfaces.

Always test adhesives on real surfaces—surface energy, texture, and cleanliness dramatically affect performance.

Durability: Built to Last

Durability ensures that the RFID label continues to perform despite environmental stress, handling, and wear.

Key Durability Factors

- Face Material

- TT Paper: Cost-effective, good for retail or indoor use.

- PET (Polyester): Resistant to moisture, abrasion, and chemicals.

- Polyimide: High-temperature resistance (up to 300°C+), ideal for electronics or industrial processes.

- Environmental Resistance

- IP-rated constructions for dust and water exposure.

- UV-resistant materials for outdoor use.

- Chemical-resistant coatings for labs, manufacturing, and healthcare.

- Print Protection

- Overlaminates protect against abrasion and chemicals.

- Varnishes offer light protection for lower-cost applications.

- Thermal transfer ribbons (resin) provide the highest durability.

- Read Reliability Over Time

- Antenna integrity must remain intact despite bending or abrasion.

- Chip bonding quality affects long-term performance.

- Protective layers prevent antenna detuning or damage.

Durability Needs by Industry

Retail

- Moderate durability.

- Focus on aesthetics, branding, and cost efficiency.

- Typically uses paper or PET smart labels.

Warehouse & Logistics

- High abrasion resistance.

- Strong adhesives for rough handling.

- PET or ruggedized labels preferred.

Healthcare & Pharma

- Must withstand sterilization, chemicals, and frequent cleaning.

- Polyimide or chemical-resistant PET labels are common.

Field Service & Outdoor Assets

- Weatherproof, UV-resistant, and rugged.

- On-metal or industrial-grade labels with foam layers.

Electronics Manufacturing

- High-temp labels for PCB tracking.

- Polyimide labels that survive reflow ovens.

Pro Tip: Pre-Encoded vs. Custom Labels

Pre-Encoded Labels

- Ideal for pilots, small deployments, or standardized SKUs.

- Reduce setup time and eliminate encoding errors.

- Often locked to prevent tampering.

Custom-Encoded Labels

- Essential for dynamic inventory environments.

- Integrate seamlessly with ERP, WMS, or MES systems.

- Support serialized EPCs, custom memory structures, and security features.

Final Thoughts

RFID labels are not one-size-fits-all. They are engineered components that must align with your:

- Surface type

- Environmental conditions

- Read range requirements

- Operational workflow

- Durability expectations

Choosing the right combination of format, adhesive, and durability ensures:

- Higher read accuracy

- Faster inventory cycles

- Lower operational costs

- Longer label lifespan

- Better ROI on your RFID system

Recent Posts

-

How RFID Handheld Readers Can Be Used with GPS for Asset Location Tracking

Asset tracking has become a critical challenge across industries such as logistics, warehousing, hea …Feb 26th 2026 -

How to Choose the Best RFID Printer: A Complete Buyer's Guide

1. What is an RFID Printer (and Why Do You Need One)? An RFID (Radio Frequency Identification) print …Feb 17th 2026 -

Zebra RFD40-M Premium Plus UHF RFID Sled

The Zebra RFD40M Premium Plus UHF RFID Sled is a modular, high-performance RFID reader that attaches …Feb 9th 2026