RFID Installation Mistakes to Avoid

Radio Frequency Identification (RFID) technology offers tremendous benefits in asset tracking, inventory management, access control, and supply chain visibility. However, despite its many advantages, RFID implementation is a nuanced process. Many companies experience underperformance, poor read rates, or complete system failure—not because the technology is flawed, but due to common installation mistakes.

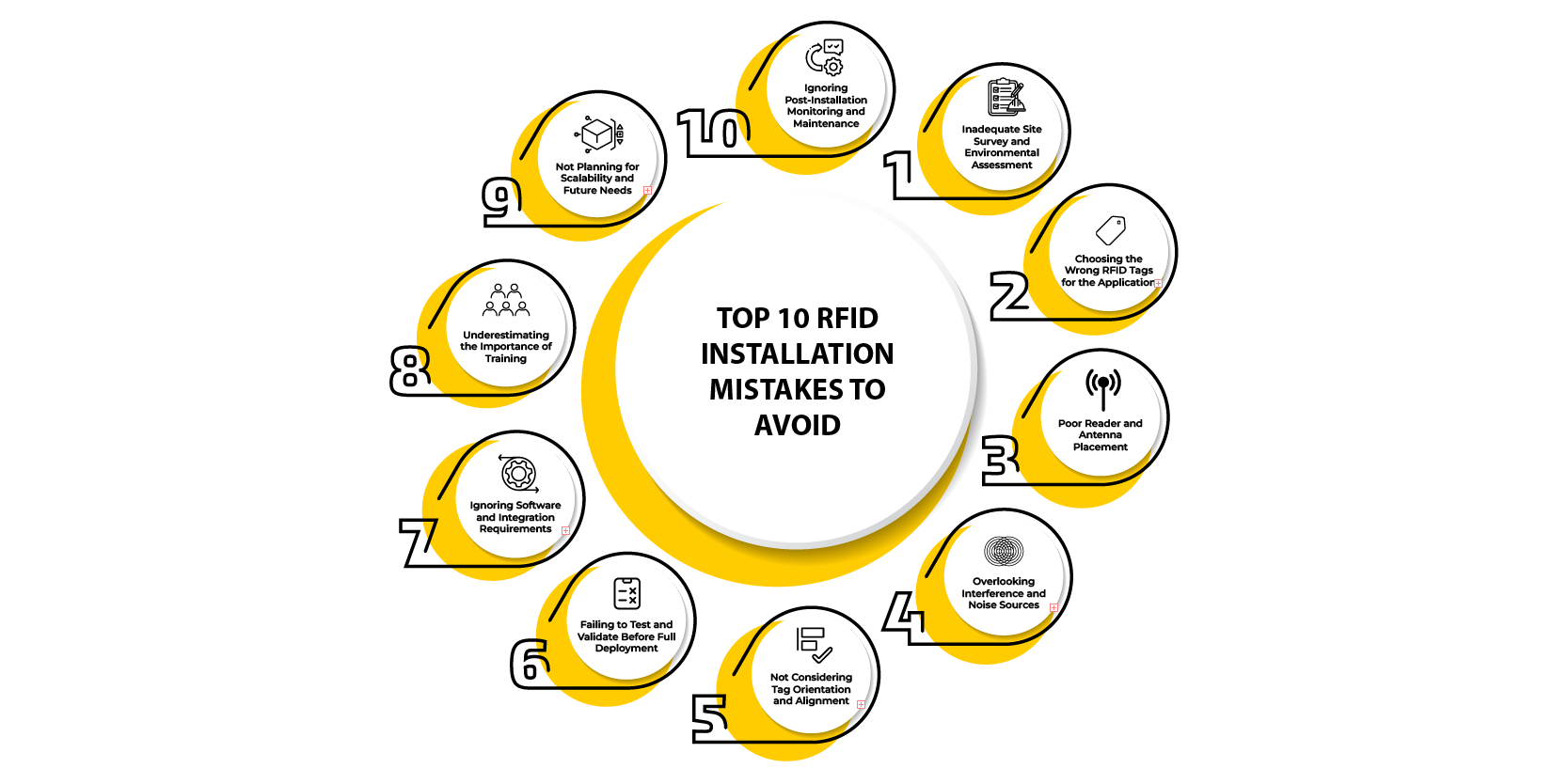

This article dives deep into the top 10 RFID installation mistakes that organizations must avoid to ensure the successful deployment and long-term performance of RFID systems.

1. Inadequate Site Survey and Environmental Assessment

Why It’s a Mistake:

Skipping or rushing the site survey is one of the most critical and costly mistakes in RFID deployments. Without a thorough assessment of the environment, it's impossible to design an optimal RFID system.

Consequences:

- Signal interference will hamper.

- Poor read accuracy

- Tag shadowing or dead zones

Best Practices:

- Perform a comprehensive RFID site survey before installation.

- Analyze environmental factors, including metal structures, moisture, temperature, and electromagnetic interference.

- Use spectrum analyzers and handheld readers to test various spots.

- Identify high-traffic zones, choke points, and optimal tag read zones.

2. Choosing the Wrong RFID Tags for the Application

Why It’s a Mistake:

RFID tags come in various types (passive, active, semi-passive) and frequencies (UHF, HF, LF). Selecting the wrong tag type or form factor can lead to performance issues.

Consequences:

- Tags are not reading at the required distances

- Tags failing under certain environmental conditions

- Reduced data capture accuracy

Best Practices:

- Match tag specifications with asset types and environmental conditions.

- Use metal-mount tags for metallic surfaces and rugged tags for outdoor or harsh environments.

- Consider RFID tag size, attachment method, read range, and durability.

3. Poor Reader and Antenna Placement

Why It’s a Mistake:

Improper placement of readers and RFID antennas can result in weak signal strength, overlapping read zones, or blind spots.

Consequences:

- Missed reads or duplicate reads

- Interference between RFID Antennas

- Increased hardware cost without added value

Best Practices:

- Place antennas at strategic locations such as dock doors, portals, conveyor belts, or entry points.

- Use simulation tools or physical testing to determine the best height, angle, and orientation.

- Avoid placing antennas too close to reflective surfaces or each other.

4. Overlooking Interference and Noise Sources

Why It’s a Mistake:

RFID systems operate on radio frequencies and can be highly sensitive to interference from other wireless devices, metal, or environmental noise.

Consequences of Interference and Noise Sources :

- Inconsistent RFID tag reads

- Reader performance degradation

- System downtime

Best Practices:

- Identify and mitigate sources of RF interference, such as Wi-Fi routers, microwaves, or industrial equipment.

- Use shielded cables and filters to reduce electromagnetic interference.

- Select RFID hardware with built-in anti-collision and noise filtering capabilities.

5. Not Considering Tag Orientation and Alignment

Why It’s a Mistake:

RFID antennas emit radio waves in specific patterns. If RFID tags are misaligned with the antenna's polarization or orientation, it can drastically reduce read rates.

Consequences:

- Unreliable data collection

- Tags not detected during movement

- Decreased system efficiency

Best Practices in this case:

- Test tag placement and orientation thoroughly during pilot phases.

- Use omnidirectional antennas if tag orientation cannot be controlled.

- Ensure the tag’s antenna is aligned with the reader’s antenna polarization.

6. Failing to Test and Validate Before Full Deployment

Why It’s a Mistake:

Jumping straight into full-scale deployment without pilot testing is a common mistake that often leads to failure or rework.

Consequences of Test and Validate Before Full Deployment:

- Waste of resources on ineffective installations

- Inability to diagnose and fix issues post-installation

- Project delays and cost overruns

Best Practices:

- Start with a small-scale pilot test.

- Validate tag readability, system latency, and integration with backend systems.

- Adjust hardware placements and configurations based on pilot feedback.

7. Ignoring Software and Integration Requirements

Why It’s a Mistake:

RFID hardware needs compatible RFID software to collect, interpret, and process tag data. Ignoring RFID software integration leads to data silos or loss.

Consequences of Ignoring Software and Integration Requirements:

- Inaccessible or unusable RFID data

- Failure to trigger automated workflows

- A disconnect between the RFID system and business operations

Best Practices:

- Choose RFID middleware or cloud-based software that supports your use case.

- Ensure smooth integration with ERP, WMS, or inventory management systems.

- Define data formats, communication protocols (e.g., EPCIS, REST APIs), and database requirements.

8. Underestimating the Importance of Training

Why It’s a Mistake:

RFID systems involve new processes and technologies. Without proper training, employees may misuse equipment or misinterpret data, leading to potential risks.

Consequences:

- System misuse or underutilization

- Increased support and maintenance calls

- Operational inefficiencies

Best Practices:

- Train staff on RFID readers, tags, software interfaces, and troubleshooting.

- Create standard operating procedures (SOPs) for scanning, tracking, and handling RFID-tagged items.

- Conduct refresher sessions as system upgrades are made.

9. Not Planning for Scalability and Future Needs

Why It’s a Mistake:

Designing a rigid RFID system without room for growth can limit your organization's ability to expand or adapt.

Consequences:

- High cost of future upgrades

- Inability to add new features or tag types

- System obsolescence

Best Practices:

- Use modular and scalable hardware and software components.

- Plan for future tag volumes, additional read zones, and system integrations.

- Choose standards-compliant solutions (e.g., EPCglobal, ISO) to ensure interoperability.

10. Ignoring Post-Installation Monitoring and Maintenance

Why It’s a Mistake:

RFID systems need ongoing maintenance, performance checks, and updates. Many organizations neglect this once the system goes live.

Consequences:

- Gradual performance degradation

- Undetected hardware failures or dead antennas

- Loss of data integrity

Best Practices:

- Set up system diagnostics and performance monitoring dashboards.

- Schedule routine maintenance and firmware/software updates.

- Monitor read rates, hardware health, and database logs regularly.

Conclusion

Implementing RFID technology can revolutionize operations, but success hinges on careful planning, execution, and ongoing optimization. Avoiding these top 10 RFID installation mistakes will significantly enhance system performance, improve ROI, and ensure long-term reliability.

Recent Posts

-

RFID Label Sizes & Formats Guide 2026

Radio Frequency Identification (RFID) labels are the backbone of modern asset tracking, inventory ma …Jan 23rd 2026 -

RFID Labels for Inventory: Formats, Adhesives & Durability GuideMeta Description

RFID labels may look simple on the surface, but they are engineered components that directly influen …Jan 17th 2026 -

RFID Gate Portals in Retail and Warehouses

The landscape of retail and warehouse operations is undergoing a profound transformation, moving awa …Dec 18th 2025