Mount on Metal RFID Tags: How to Track Metal Assets Effectively

RFID technology has revolutionized asset tracking, but when it comes to metal surfaces, things get tricky. Unlike other materials, metal doesn't play well with RF waves. It blocks and reflects them, and it also interferes with the RFID tag’s antenna, drastically reducing read range or causing complete signal loss.

So how do you track tools, machines, containers, kegs, auto parts, and other metal assets with RFID? Fortunately, there are several proven solutions that allow RFID to function effectively in these challenging conditions.

1. Avoid Direct Placement on Metal Surfaces

If your asset has non-metal parts or packaging, placing a standard RFID tag on those areas is the easiest solution. Hanging tags or placing the tag on non-metal packaging avoids the need for specialized equipment and lets you use standard RFID labels cost-effectively.

For example, TagMatiks RFID Hang Tags (TMHT) offer a versatile solution by hanging off bars or handles, making no direct contact with the RFID metal Tags. These tags are great for temporary applications or when tags need to be reused or moved.

RFID Hang Tag

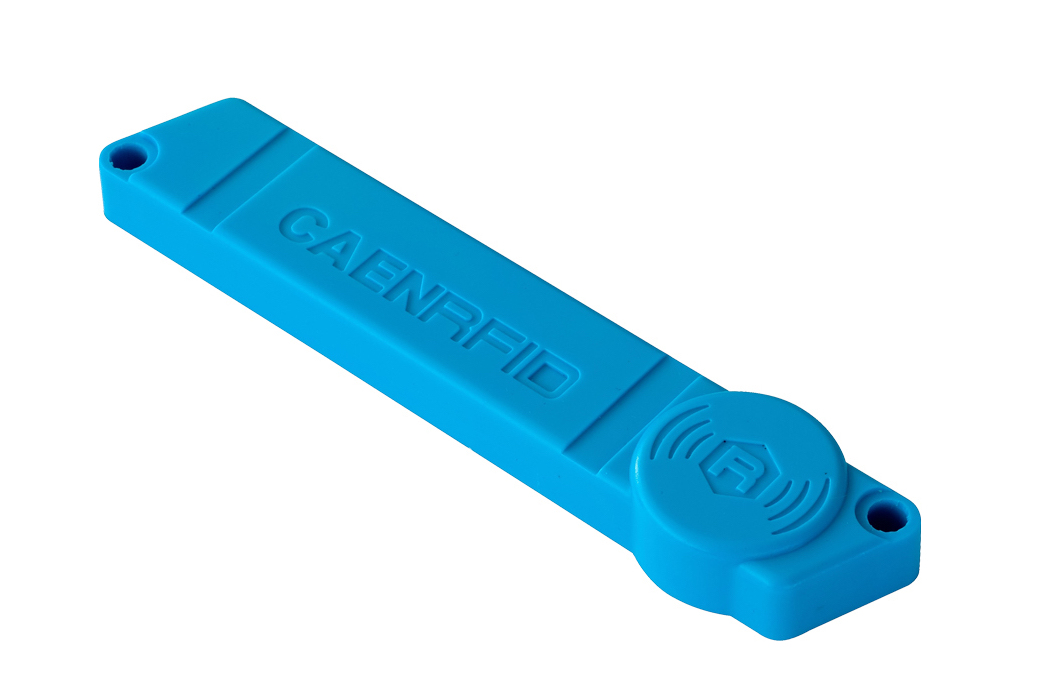

2. Use Encapsulated Mount on Metal Tags

For permanent or industrial-grade applications, mount on metal encapsulated RFID tags are the go-to solution. These tags are specially designed with encapsulation that:

- Increases durability

- Offsets the tag antenna from the metal surface

- Harnesses both direct and reflected signals

The offset and antenna design are precisely engineered to work in harmony with the metal surface, often resulting in superior read performance—sometimes even better than in non-metal environments. However, these tags are optimized for metal, so they may underperform when mounted on plastic, wood, or other surfaces.

Some advanced versions use a universal design with complete insulation from the metal, making them suitable for all surfaces.

Encapsulated Metal Mount Tags

Note: Sometimes, the tag antenna is completely insulated from the metal surface and does not use the metal to increase performance. In this case, the tag is universal and can be used for any surface, not just metal.

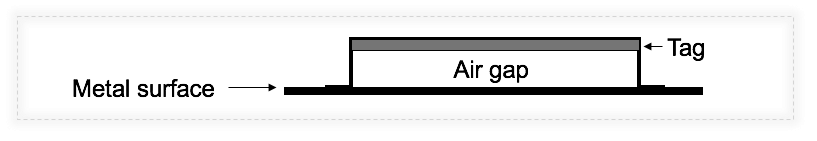

Metal Mount RFID Tag Diagram

3. Try Mount on Metal RFID Labels

When you need a lower-profile or printable option, mount on metal RFID labels are ideal. These labels are:

- Thicker than standard RFID labels

- Designed with a built-in metal-insulating layer

- Tuned specifically for metal surface performance

While many must be preprinted, innovations like the Confidex Silverline series offer labels that can be printed and encoded using standard desktop RFID printers. These are perfect for mid-range metal asset tracking where space and aesthetics matter.

4. Consider Semi-Passive or Active RFID Tags

When tracking high-value assets or operating in metal-heavy environments like factories or shipyards, semi-passive or active RFID tags offer robust performance. These tags are:

- Always encapsulated (offering durability and metal insulation)

- Equipped with power sources (batteries)

- Capable of stronger signal transmission and better signal reception

The presence of a transmitter (in active tags) helps to counteract signal reflection and bending, making them highly effective—but at a higher cost. These tags are best reserved for high-value or mission-critical tracking applications.

Final Thoughts

RFID struggles with metal, but the right tools can overcome the challenge. Whether it’s through creative placement, encapsulated tags, specialized labels, or powered tags, you have options to ensure your RFID system performs reliably—even in the most metal-intensive environments.

Selecting the right solution depends on your asset type, durability needs, and budget. With the right strategy, tracking metal tools, machines, and containers with RFID can be just as seamless as tracking anything else.

Recent Posts

-

RFID Gate Portals in Retail and Warehouses

The landscape of retail and warehouse operations is undergoing a profound transformation, moving awa …Dec 18th 2025 -

Why Add RFID to Your Labeling Strategy in 2026

In 2026, the global supply chain is undergoing a seismic transformation. From omnichannel retail to …Dec 11th 2025 -

Zebra Handheld RFID Readers for Retail Efficiency

In the dynamic world of retail, where inventory accuracy, customer experience, and operational effic …Nov 28th 2025